What is the difference between heat press and silk screen printing?

Heat press and screen printing, or silkscreen, are two of the most widely used techniques for businesses and creators looking to customize clothing and merchandise. Each method has its own unique advantages, and the ideal choice depends on key factors such as design complexity, material compatibility, and order quantity.

In this guide, we'll break down the differences between heat press and silkscreen, focusing on the critical role that a screen printer plays in achieving professional, lasting results.

I. What is silkscreen?

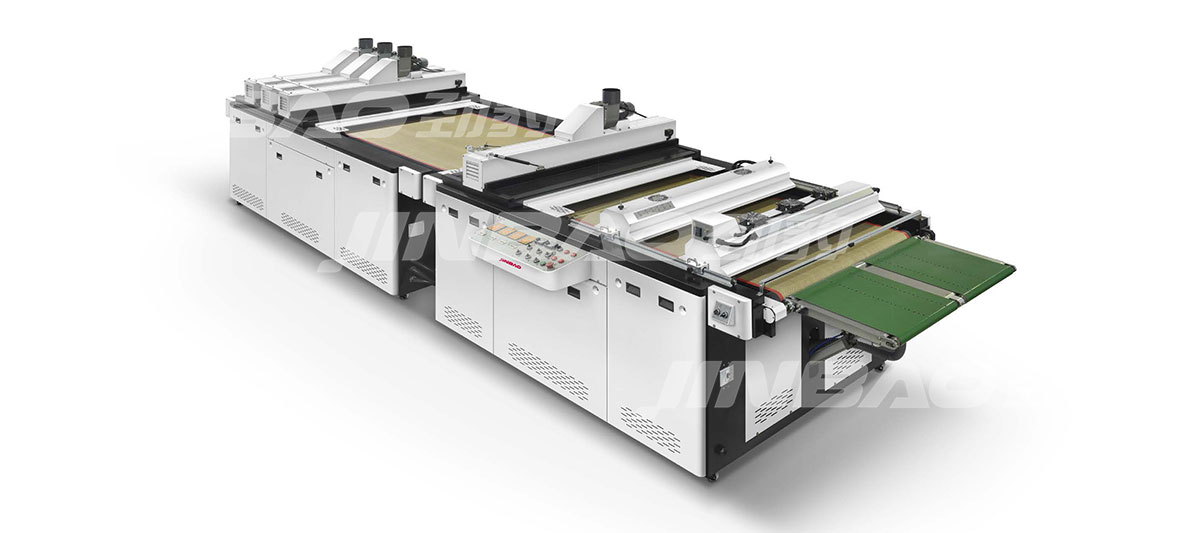

Screen printing is a traditional method that uses a screen printer to apply ink through a fine-mesh stencil onto fabric or other surfaces. Each end color in a design requires a separate screen, making it ideal for bulk orders with simple designs.

How a screen printer works:

1. The pattern is engraved onto the screen using an induction emulsion.

2. The screen is placed over the fabric and ink is applied to the screen with a squeegee.

3. The opening areas of the pattern are embossed to print the pattern onto the fabric.

4. The printed fabric is then heat cured for increased durability.

Advantages of screen printing:

Long-lasting vibrant colors, economical for large orders, works on a variety of materials (cotton, polyester, wood, glass, etc.), smooth and professional print finish

Disadvantages of screen printing:

High setup costs for small batches

Not suitable for complex multi-color designs

Requires skilled operators of screen printers

II. What is heat press printing?

Heat press printing uses heat and pressure to displace a pre-printed pattern (usually printed on sublimation paper or vinyl) onto fabric. It is a digital printing method that works best for small batches, complex full-color patterns.

How heat press printing works:

1. The pattern is printed on the highest grade paper or cut from the hottest vector (HTV).

2. The face is placed on the fabric and pressed with a heat press.

3. The protein is permanently exfoliated onto the tissue through heat and pressure.

Advantages of heat press printing:

Great for detailed, photo-fresh prints, no minimum order quantity, quicker to set up than screen printing, suitable for polyester and blended fabrics

Disadvantages of heat press printing:

Not as durable as screen printing (may crack over time), not consistent for custom fabrics (no special orders), higher unit cost for bulk orders, higher labor costs

III. Main differences between screen printers and heat presses

| Features | Screen printing | Heat press printing |

| Best suited | Bulk orders, simple designs | Small batches, detailed designs |

| Durability | Definitely long-lasting | May fade or crack over time |

| Setup cost | High | Low |

| Production speed | Slower to set up, faster for large batches | Faster for single pieces, slower for batches |

| Color options | Limited (end colors require separate screens) | Unlimited (full-color printing possible) |

| Construction compatibility | Best for cotton fabrics | Best for polyester and lightweight fabrics |

IV. Which method should you choose?

Choose a screen printer if:

You need large-scale production (e.g., custom t-shirts for an event).

Your designs have colors and simple shapes.

You want highest durability (e.g., for workwear or sportswear).

Choose a heat press if:

You need small batches or one-off prints.

Your designs include gradient effects, photos, or fine details.

You are using polyester or high-performance fabrics.

V. Conclusion

Screen printing and heat pressing each have their advantages. If you are looking for an affordable, long-lasting solution for bulk orders, investing in a screen printer is your best option. However, if you need fast, full-color printing, a heat press offers more flexibility.

By understanding the differences between these two methods, you can choose the best printing technique for your project and achieve professional-quality results every time.