What is the difference between flat bed and rotary screen printing?

Textile printing is a vital process in the fabric manufacturing industry, allowing for intricate designs and vibrant colors on various materials. Two of the most common methods used are flat bed screen printing and rotary screen printing. While both techniques involve pushing ink through a mesh screen to create patterns, they differ significantly in terms of speed, precision, cost, and application.

This article explores the differences between flat bed and rotary screen printing, helping you determine which method best suits your production needs.

1. Overview of Flat Bed Screen Printing

Flat bed screen printing is a traditional method where fabric is printed using flat, stationary screens. Each color in the design requires a separate screen, and the fabric moves on a conveyor belt beneath the screens.

How It Works:

The fabric is laid flat on a printing table.

A separate screen is used for each color in the design.

Ink is applied manually or automatically onto the screen and spread using a squeegee.

The fabric moves to the next screen for additional colors.

Advantages:

High Precision – Ideal for intricate and detailed designs.

Versatility – Works well on various fabric types, including thick and textured materials.

Lower Initial Cost – More affordable setup compared to rotary printing.

Disadvantages:

Slower Production Speed – Requires manual or semi-automatic operation, making it less efficient for large orders.

Higher Labor Costs– More manual intervention is needed.

Limited Repeat Length – The design size is constrained by the screen dimensions.

Best For: Small to medium batches, high-end fashion, custom designs, and fabrics requiring multiple colors with fine details.

2. Overview of Rotary Screen Printing

Rotary screen printing is a modern, high-speed method where cylindrical screens rotate continuously while fabric passes beneath them. This automated process allows for faster production compared to flat bed printing.

How It Works:

Fabric moves under rotating cylindrical screens.

Each screen corresponds to a different color in the design.

Ink is fed inside the screens and transferred onto the fabric as it moves.

Advantages:

Faster Production M - Can print thousands of meters per hour, making it ideal for bulk orders.

Continuous Patterns - No size limitations on repeat patterns.

Lower Labor Costs - Highly automated, reducing manual work.

Disadvantages:

Higher Initial Investment – More expensive machinery and setup.

Less Detail – Not as precise as flat bed printing for very fine designs.

Fabric Limitations – Works best on lightweight to medium-weight fabrics; may struggle with thick materials.

Best For: Large-scale textile production, such as apparel, home textiles, and industrial fabrics where speed and volume are priorities.

3. Key Differences Between Flat Bed and Rotary Screen Printing

| Feature | Flat Bed Screen Printing | Rotary Screen Printing |

| Speed | Slower (manual/semi-auto) | Faster (fully automated) |

| Precision | Higher detail & sharpness | Slightly less detailed |

| Cost Efficiency | Lower setup cost, higher labor | Higher setup cost, lower labor |

| Fabric Compatibility | Works on thick & textured fabrics | Best for lightweight fabrics |

| Production Volume | Small to medium batche | Large-scale production |

| Repeat Pattern Length | Limited by screen size | Unlimited continuous patterns |

4. Which One Should You Choose?

The choice between flat bed and rotary screen printing depends on your specific needs:

Choose Flat Bed Printing If:

You need high-detail, multi-color designs.

Your production volume is small or medium.

You work with thick or specialty fabrics.

Choose Rotary Printing If:

You require fast, large-scale production.

Your designs have continuous patterns.

Cost-efficiency for bulk orders is a priority.

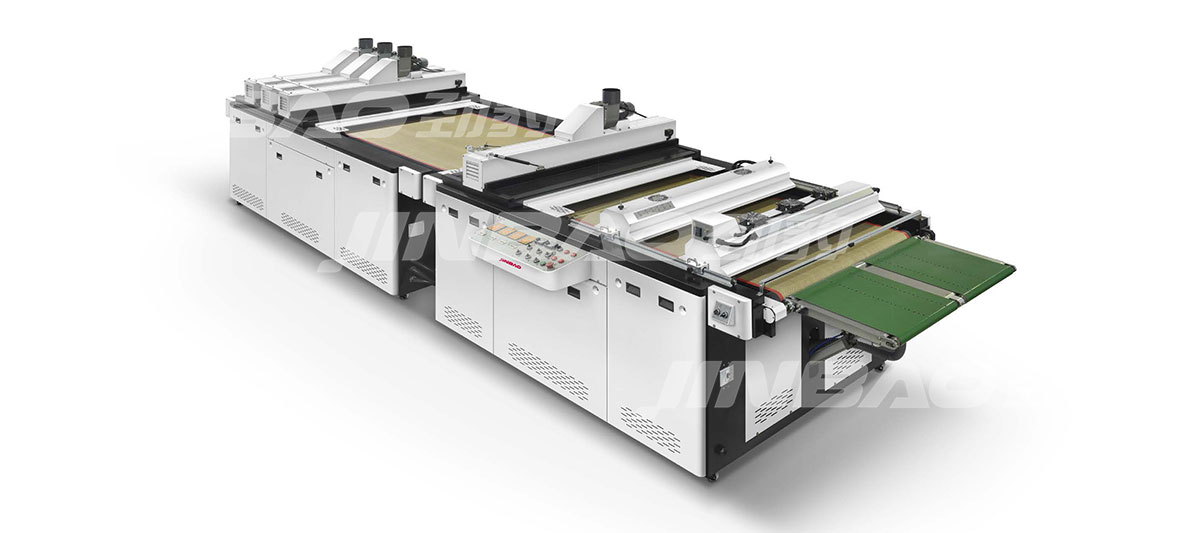

Jinbao: A Trusted Partner for Professional Screen Printing Solutions

Jinbao specializes in the design and manufacture of high-performance fully automatic screen printing machines and printing auxiliary equipment. Our products are widely used in graphic printing, post-press processing, garment transfers, textile printing, and more.

Although flatbed and rotary screen printing both have their limitations, we have combined the best features of both technologies to develop advanced automatic and semi-automatic screen printing machines. After years of innovation, our solutions cater to a wide range of applications, including:- Packaging and decal printing,Textile and apparel printing and Multi-color screen printing

Still unsure which machine is best for your needs? **Contact us** today and our professional technicians will provide **personalized, professional advice** to optimize and perfect your printing process.

5. Conclusion

Both flat bed and rotary screen printing have unique advantages, making them suitable for different applications. While flat bed printing excels in precision and versatility, rotary printing dominates in speed and efficiency for mass production.

Understanding these differences helps manufacturers, designers, and businesses select the best method for their textile printing needs, ensuring quality, cost-effectiveness, and optimal production output.