Stop vs. Swing Cylinder Technologies Reshape Industrial Printing

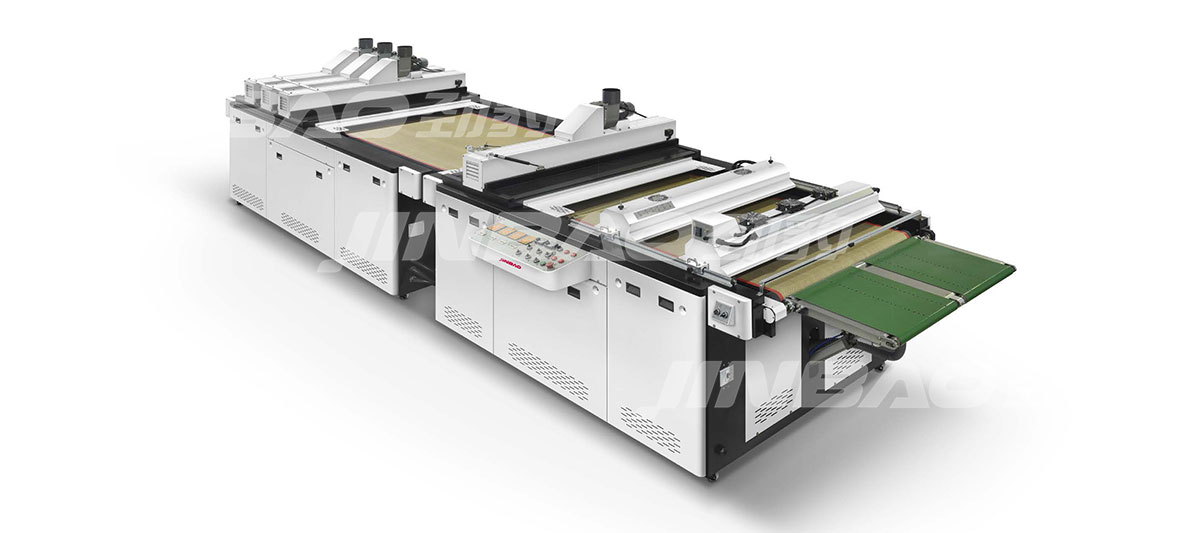

The graphic arts manufacturing sector is witnessing a paradigm shift with the emergence of advanced cylinder-driven screen printing systems. Two distinct technologies - the Stop Cylinder Screen Printing Machine and Swing Cylinder Screen Printing Machine - are now dominating technical discussions among industrial printing specialists, each offering unique solutions for different production requirements.

Precision Engineering Meets Automated Workflows

Modern Stop Cylinder Screen Printing Machines have redefined precision in multi-color registration through their patented cylinder immobilization mechanism. These systems employ servo-driven intermittent motion technology, achieving micron-level accuracy during substrate impression phases. The stationary cylinder configuration enhances stability for intricate graphic reproductions, particularly when handling delicate substrates requiring <2% dot gain maintenance.

Conversely, Swing Cylinder Screen Printing Machines are gaining traction in high-volume production environments through their continuous motion architecture. The pendulum-style cylinder retraction system enables non-stop substrate feeding while maintaining 0.05mm positional repeatability. This oscillation mechanism significantly reduces machine cycle times, with some models achieving 4,200 impressions per hour in full-automatic operation.

Technical Differentiation and Application Spectrum

*Key performance divergences emerge in their drive systems and energy consumption profiles:

1. Stop Cylinder variants utilize programmable cam-driven articulation, ideal for UV-curable ink applications requiring extended dwell times

2. Swing Cylinder models incorporate energy-regenerative swing arms, reducing power consumption by 18-22% in continuous runs

*Industry analysts highlight growing adoption of hybrid configurations combining both technologies. The latest generation machines now feature:

1. Adaptive impression pressure control (50-500N/cm² adjustable range)

2. Intelligent ink viscosity monitoring systems

3. Automated screen tension compensation

4. CIP4-compliant job parameter recall

Market Response and Sustainability Impacts

Major packaging converters report 30-40% setup time reductions when using Stop Cylinder machines for short-run premium packaging jobs. The pharmaceutical sector particularly benefits from their cleanroom-compatible designs and particulate containment shrouds.

Swing Cylinder adopters in the textile industry emphasize the technology's compatibility with low-migration ink systems and rapid curing modules. Environmental metrics show 15% reduction in solvent emissions compared to conventional reciprocating systems, aligning with EPA Tier IV manufacturing standards.

Future Development Trajectory

Manufacturers are now integrating IIoT capabilities into both platforms, with:

Predictive maintenance algorithms analyzing harmonic vibrations

Cloud-based plate wear monitoring

AI-driven registration error compensation

"The convergence of mechanical precision and Industry 4.0 connectivity is creating unprecedented value in cylinder-driven printing," notes Dr. Elena Marquez, CTO of Graphic Arts Technologies International. "Our next-gen systems will feature quantum-tunneling sensors for real-time impression force mapping."

As the global screen printing equipment market approaches $3.8B by 2026, the stop vs. swing cylinder full automatic screen printing machine debate continues to drive innovation in substrate handling, energy efficiency, and color management systems across multiple industrial printing verticals.