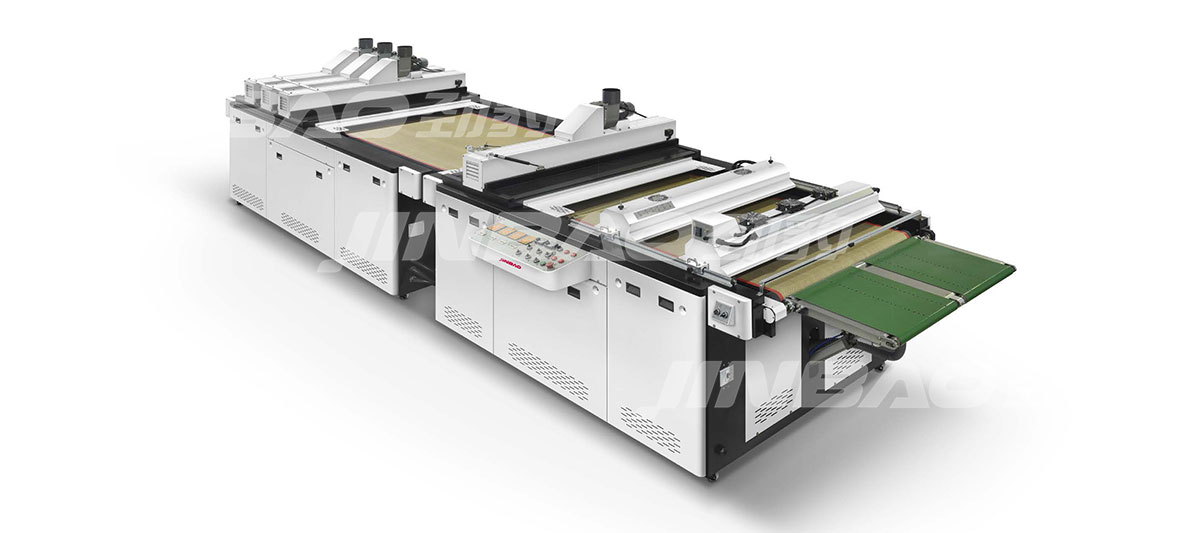

What is Semi-Automatic Screen Printing Machine?

1. Definition

Semi-Automatic Screen Printing Machine is a printing device between manual screen printing and fully automatic screen printing. It combines the flexibility of manual operation with a certain degree of automation, and is used to print on various flat or slightly curved surfaces. For example, it can print patterns on T-shirts, plastic products, metal plates, glass products, ceramics and other materials.

2. Working Principle

The basic principle of screen printing is to transfer the ink through the mesh of the screen to the surface of the printed object through the extrusion of the scraper. In a semi-automatic screen printing machine, the pattern to be printed is first made on the screen, and some areas on the screen are blocked, and only the mesh of the pattern part is transparent.

Place the object to be printed on the workbench and fix the position, and then start the printing process through the machine's partial automation functions, such as automatic positioning (some models have) or manually adjust the printing position. The machine will control the screen to descend (or the printed object to rise) so that the screen is in contact with the surface of the printed object. Next, the scraper scrapes over the screen, and the ink seeps out of the mesh of the screen under the pressure of the scraper and prints on the surface of the object, thus completing a printing. After that, the screen rises (or the printed object falls), the printed product can be taken out, and a new object to be printed can be put in, and the above process is repeated.

3. Main structural components

Screen fixing device: used to firmly fix the screen, and the position and angle of the screen can be adjusted to ensure the accuracy of the printed pattern. This device usually has a clamping mechanism or a slot, which can easily install and remove the screen.

Printing workbench: It is a platform for placing the object to be printed. Its surface is generally flat, and some workbenches also have adsorption functions (such as vacuum adsorption) to better fix the printed object and prevent it from moving during the printing process. The height and position of the workbench can usually be adjusted to adapt to printed objects of different thicknesses and different printing requirements.

Scraper device: It consists of a scraper and a scraper bracket. The scraper is generally made of materials such as rubber or polyurethane, and has a certain elasticity and hardness. The scraper bracket can adjust the angle and pressure of the scraper. The appropriate scraper angle and pressure are crucial for ink transfer and printing quality. During the printing process, the scraper moves along the surface of the screen to push the ink through the mesh.

Transmission system: including motors, belts, chains, gears and other components. The motor provides power and realizes the lifting and lowering of the screen, the movement of the workbench (if any) or the movement of the scraper through transmission methods such as belts, chains or gears. The accuracy and stability of the transmission system directly affect the accuracy and repeatability of printing.

Control system: This is the "brain" of the semi-automatic screen printing machine, usually including a control panel and a control circuit. The operator can set printing parameters such as printing speed, scraper pressure, screen descent height, etc. through the control panel. The control circuit is responsible for converting the operator's instructions into the actions of the motor and other actuators to ensure that the printing process is carried out according to the set requirements.

4. Advantages

High cost-effectiveness: Compared with fully automatic screen printing machines, semi-automatic screen printing machines are cheaper. For small and medium-sized enterprises or just starting printing businesses, the purchase cost is more affordable. At the same time, its maintenance cost is relatively low, because its structure is relatively simple, and it is convenient to repair when a fault occurs.

High flexibility: The operator can manually intervene according to the actual situation during the printing process. For example, for some special shapes or irregular printing objects, the parameters such as printing position, angle and pressure can be flexibly adjusted to obtain satisfactory printing effects. Moreover, it can easily replace different screen plates and print a variety of patterns, which is suitable for small batches and diversified printing tasks.

Good printing quality: Through reasonable setting of printing parameters and skilled operation, semi-automatic screen printing machines can produce high-quality printed products. It can accurately control factors such as printing pressure and speed, so that the ink can evenly pass through the mesh of the screen plate, thereby forming a clear and colorful pattern on the surface of the object.

5. Disadvantages

Relatively low production efficiency: Due to the need for manual participation in some operations, such as placing and removing printed objects, the production speed of semi-automatic screen printing machines is slower than that of fully automatic screen printing machines. In large-scale, high-efficiency printing production, it may not meet the needs of fast production.

High skill requirements for operators: In order to obtain good printing results, operators need to have certain knowledge and skills in screen printing. For example, they need to be proficient in the adjustment of printing parameters, the operation skills of the scraper, and the installation and maintenance of the screen. Otherwise, the printing quality may be unstable or there may be printing defects.