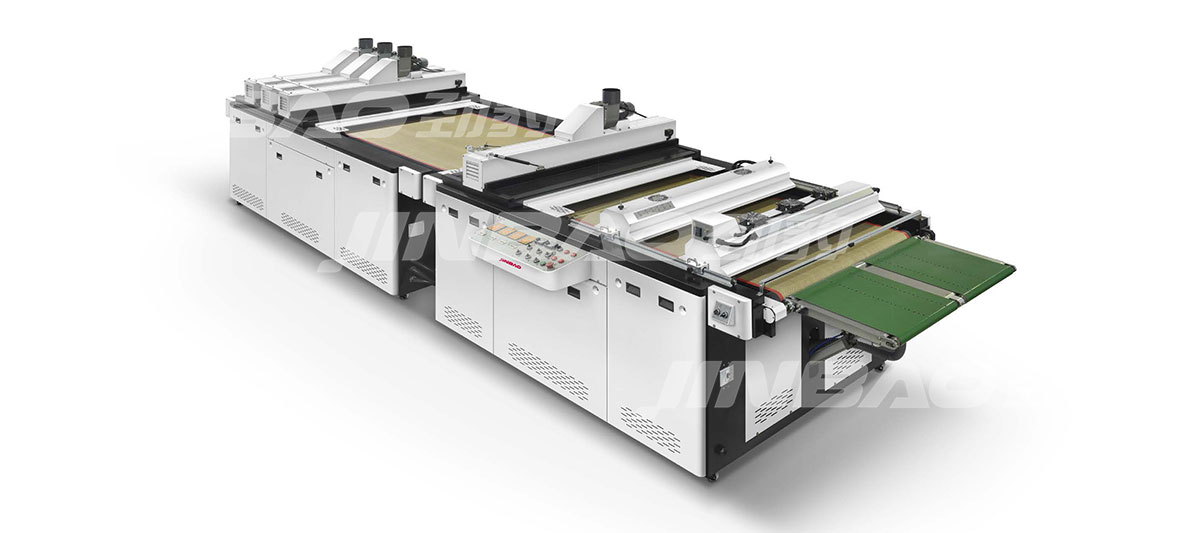

Automatic Screen Printing Machine: Revolutionizing the Printing Industry

In the ever-evolving world of printing technology, the Automatic Screen Printing Machine has emerged as a game-changer, bringing efficiency, precision, and versatility to the forefront.

What is an Automatic Screen Printing Machine?

An Automatic Screen Printing Machine is a sophisticated piece of equipment designed to automate the process of screen printing. It uses a screen mesh to transfer ink onto a substrate, such as fabric, paper, plastic, or glass. The machine is capable of performing multiple printing operations in a sequential and precise manner, eliminating the need for manual intervention in many of the traditional printing steps.

How Does It Work?

1. Screen Preparation

The first step involves preparing the screen. A fine mesh screen is coated with a photosensitive emulsion. A design is then transferred onto the screen using a photographic process or direct imaging. The areas that are not part of the design are blocked off, while the open areas allow the ink to pass through.

2. Ink Application

The automatic screen printing machine is equipped with an ink reservoir and a squeegee system. The squeegee applies pressure on the ink, forcing it through the open areas of the screen and onto the substrate below. The machine can control the amount of ink applied, ensuring consistent coverage and thickness.

3. Substrate Placement and Alignment

The substrate to be printed is placed on a conveyor belt or a printing platform. The machine uses advanced alignment systems, such as optical sensors or mechanical guides, to ensure that the design is accurately printed on the substrate in the correct position. This precision is crucial, especially when printing multiple colors or complex patterns.

4. Printing Cycle

Once the substrate is in place and aligned, the printing process begins. The machine moves the screen and the squeegee across the substrate, depositing the ink in the desired pattern. After each print, the substrate is either advanced to the next printing station (if multiple colors are being used) or removed for further processing.

Advantages of Automatic Screen Printing Machines

1. Increased Efficiency

Automatic machines can operate continuously with minimal downtime. They can print a large number of substrates in a short period, significantly increasing production output compared to manual printing methods. This is especially beneficial for high-volume printing jobs, allowing businesses to meet tight deadlines and fulfill large orders quickly.

2. Precision and Consistency

The advanced control systems and mechanical components of automatic screen printing machines ensure precise alignment and consistent ink application. This results in high-quality prints with sharp details and even color distribution. Every print is virtually identical, reducing the likelihood of errors and rejects, which in turn saves costs and improves customer satisfaction.

3. Versatility

These machines can handle a wide variety of substrates and printing applications. Whether it's printing t-shirts, posters, packaging materials, or electronic circuit boards, the Automatic Screen Printing Machine can be adjusted and configured to meet different requirements. It can print different colors, gradients, and complex designs with ease, making it a versatile tool in various industries.

4. Labor Savings

By automating the printing process, the need for extensive manual labor is reduced. This not only saves on labor costs but also frees up employees to focus on other important tasks such as quality control, machine maintenance, and product design. Additionally, it reduces the physical strain on workers associated with manual printing, improving workplace safety and ergonomics.

5. Cost-Effective in the Long Run

Although the initial investment in an Automatic Screen Printing Machine may be relatively high, the long-term benefits in terms of increased productivity, reduced waste, and lower labor costs make it a cost-effective solution. Over time, businesses can achieve a higher return on investment as they are able to produce more quality prints with fewer resources.

Applications in Different Industries

1. Textile Industry

In the textile industry, automatic screen printing machines are widely used for printing designs on fabrics. T-shirts, sportswear, curtains, and bed linens are just a few examples of products that can be beautifully decorated with intricate patterns and vibrant colors using these machines. The ability to print large quantities quickly and with consistent quality makes it an ideal choice for clothing manufacturers and textile decorators.

2. Packaging Industry

Packaging plays a crucial role in product marketing and protection. Automatic screen printing machines are used to print logos, product information, and decorative elements on packaging materials such as boxes, cartons, and labels. The precise printing capabilities ensure that the packaging is visually appealing and the information is clearly legible, enhancing the overall brand image and product value.

3. Advertising and Promotional Industry

Posters, banners, and promotional materials require eye-catching designs and high-quality printing. Automatic screen printing machines can produce large-format prints with vivid colors and sharp details, making them perfect for advertising campaigns and promotional events. They can help businesses create impactful visual displays that attract the attention of customers and effectively communicate their message.

4. Electronic Industry

In the electronic industry, automatic screen printing machines are used for printing circuit boards and other electronic components. The precise and consistent printing of conductive inks and solder masks is essential for the proper functioning and reliability of electronic devices. These machines can meet the strict requirements of the electronics manufacturing process, ensuring high-quality and accurate printing.

In conclusion

The Automatic Screen Printing Machine has revolutionized the printing industry with its efficiency, precision, and versatility. It has become an essential tool in various industries, enabling businesses to produce high-quality prints in large quantities while reducing costs and improving productivity. As technology continues to advance, we can expect even more exciting innovations and applications in the future, further enhancing the capabilities of these remarkable machines and driving the growth of the printing industry. Whether you are in the textile, packaging, advertising, or electronics industry, understanding the capabilities and potential of the Automatic Screen Printing Machine can help you stay competitive and meet the ever-changing demands of the market.