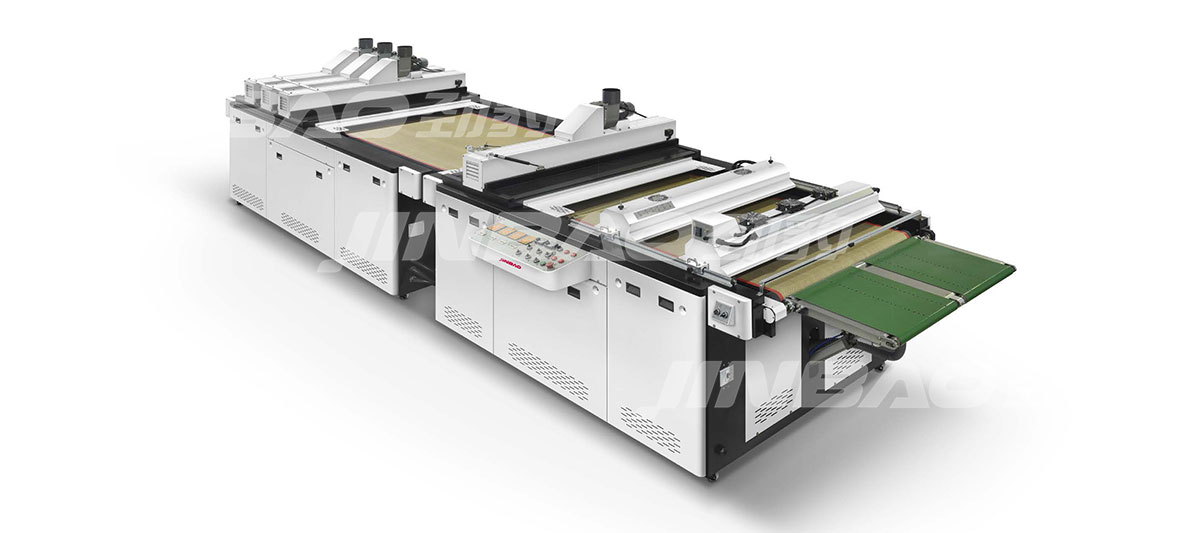

The Compatibility of Cold Foil Machine with Different Materials: Unlocking Diverse Printing Effects

In the printing and packaging sectors, the Cold Foil Machine can endow various materials with a dazzling metallic touch. However, due to distinct physical and chemical traits of different materials, understanding their compatibility with this machine is vital for an ideal cold - foiling outcome.

I. Compatibility with Paper

Paper, a staple in printing, shows diverse results when processed by the Cold Foil Machine.

1. Coated Paper

Its smooth surface allows for excellent compatibility. During cold - foiling, the UV adhesive evenly coats, ensuring firm metal - foil adhesion. This results in sharp, lustrous patterns, like on high - end magazine covers.

2. Cardboard

With high stiffness and density, cardboard can bear more pressure, facilitating metal - foil combination. For instance, in high - end cosmetic packaging, cold - foiling on cardboard elevates the product's image.

3. Specialty Paper

Specialty papers, such as art and textured ones, require parameter adjustments based on their unique textures. This creates a rich, three - dimensional cold - foiling effect, often used in art prints and high - end invitations.

II. Compatibility with Plastic Films

Plastic films, widely used in packaging, demand multifaceted considerations.

1. PET Film

Though it has good properties, its low - tension surface needs pre - treatment like corona processing. This improves adhesive adhesion, leading to a high - gloss, durable cold - foiling effect, as seen in food - packaging PET films.

2. PP Film

PP film's low surface tension and high crystallinity pose challenges. Using a specialized UV adhesive and optimizing machine parameters can achieve a satisfactory cold - foiling result, increasingly applied in daily - use packaging and labels.

III. Compatibility with Other Materials

1. Metal Materials

Cold - foiling on metal is rare but used for metal handicrafts and electronics. The metal surface needs cleaning and pre - treatment to enhance adhesive adhesion. Temperature control is also crucial due to its high thermal conductivity.

2. Fabric Materials

Cold - foiling on fabrics adds a fashion edge. However, due to their soft and porous nature, a fabric - specific UV adhesive is needed, and penetration must be controlled. Pressure and speed should be adjusted according to fabric type and thickness, like for clothing brand logos.

In summary, the Cold Foil Machine's compatibility with different materials is a complex yet creative process. By grasping material features and adjusting parameters, diverse and satisfying cold - foiling effects can be achieved, fueling innovation in the printing and packaging industries.