The Revolutionary Force in the Textile Printing and Dyeing Industry

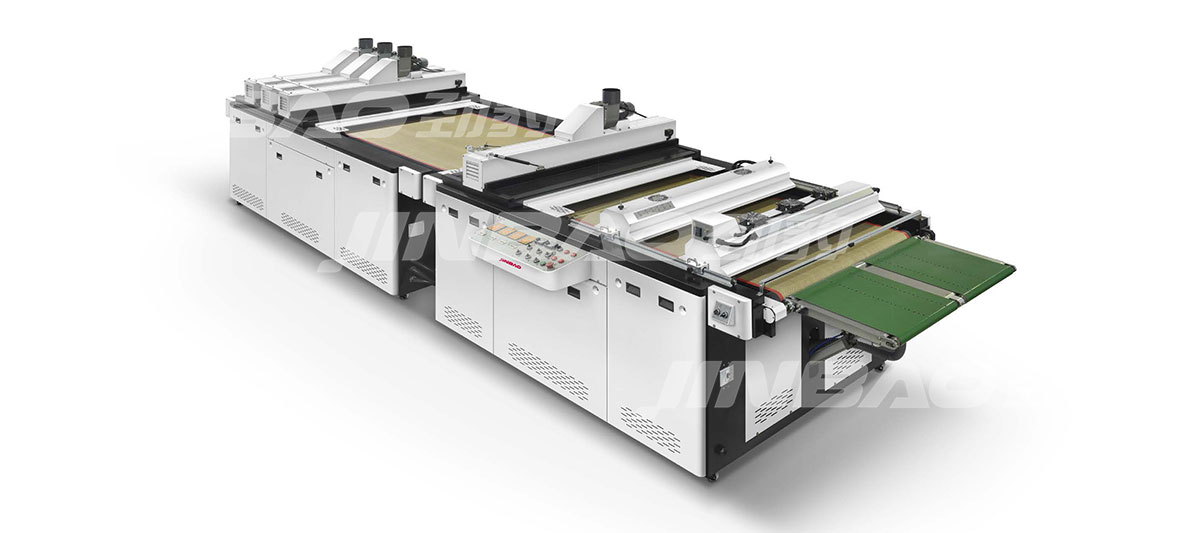

In the textile printing and dyeing industry, Automatic Stop Rotary Screen Printing Machines have become a key equipment to boost production efficiency and product quality by virtue of their excellent performance. This type of printing machine uses a continuous seamless cylindrical screen for printing and is a kind of screen printing machine.

The working principle of the rotary screen printing machine is unique and efficient. Its rotary screen is usually made of metal nickel and has patterns composed of holes. It is installed on the frames on both sides of the printing machine. The color paste squeegee is installed on the squeegee holder inside the rotary screen, and the color paste enters the rotary screen through the squeegee holder by the slurry feeding pump. During printing, the fabric to be printed advances with the circulating seamless rubber guide belt. When the guide belt runs near the machine head, a layer of fabric pasting paste or thermoplastic fabric pasting resin is applied by the sizing device to make the fabric stick tightly to the guide belt without loosening. The rotary screen rotates at a fixed position above the fabric, and the printing color paste is extruded through the holes of the rotary screen onto the fabric by the squeegee. After that, the fabric enters the dryer, and the guide belt runs in a cycle under the machine. It is washed with water and the water droplets are scraped off by the squeegee under the machine, and then the above printing process is repeated.

Automatic Stop Rotary Screen Printing Machines have many advantages. The nickel screen is lightweight, which makes the operations of loading and unloading the rotary screen, pattern matching and adding slurry very convenient, effectively reducing the labor intensity of workers. It has a high output and few limitations on the number of color sets. It operates under tension-free conditions during the processing, making it suitable for printing easily deformable fabrics and wide fabrics without the need for backing cloth. However, it also has certain limitations. For example, it is not easy to print fine patterns such as moiré and fine lines.

In terms of classification, rotary screen printing machines can be divided into three types according to the arrangement of the rotary screen: vertical, horizontal and radial. Among them, the horizontal rotary screen printing machine is the most commonly used. The horizontal rotary screen printing machine was first introduced by Stork of the Netherlands in 1963. It combines the high production efficiency of the roller printing machine and the characteristics of the flat screen printing machine, which can print large patterns with rich colors. It is recognized as a printing machine with a major breakthrough in printing technology. With the rapid increase in wide fabrics, chemical fiber fabrics and elastic fabrics, this type of printing machine has also developed rapidly.

In terms of application, rotary screen printing machines are widely used in synthetic fibers, cotton and their blended fabrics, and synthetic fiber filament fabrics. They are also used in the printing of transfer printing paper. However, the printing of silk fabrics is still in the initial exploration stage.

Automatic Stop Rotary Screen Printing Machines play an important role in the textile printing and dyeing industry. Although there are some drawbacks, with the continuous development and improvement of technology, it is expected to further enhance its performance in the future, bringing more innovation and development opportunities to the industry.