The Benefits and Applications of Cold Foil Machines

In the ever-evolving world of printing and packaging, the quest for eye-catching and high-quality finishes is relentless. Among the many innovations that have transformed the industry, cold foil technology stands out for its ability to create brilliant metallic effects on printed materials. This article delves into the workings, benefits, and diverse applications of cold foil machines.

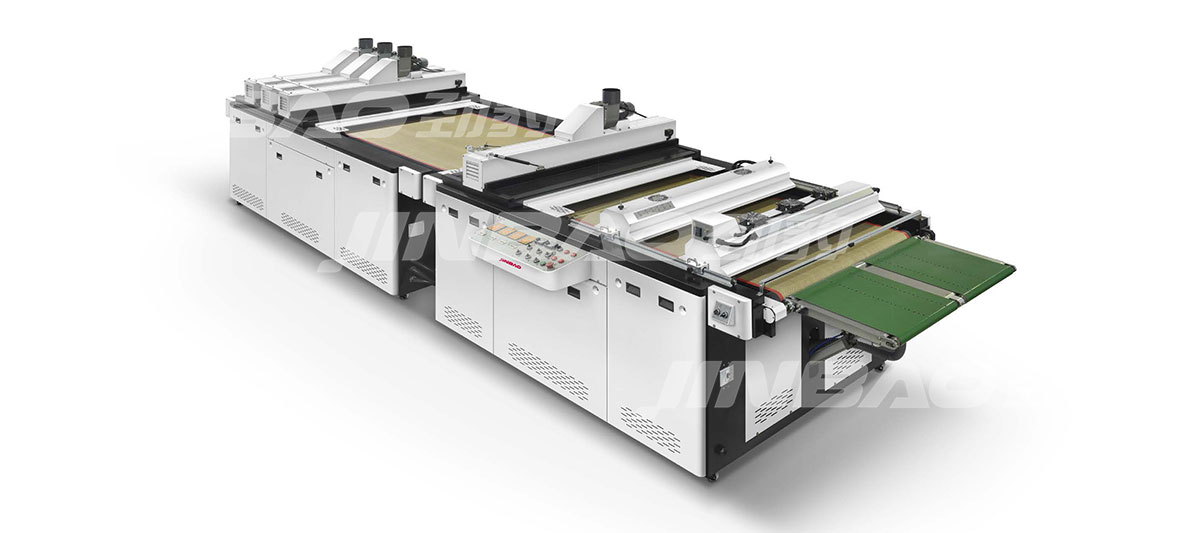

What is a Cold Foil Machine?

A cold foil machine is a specialized piece of equipment used to apply metallic foils to a substrate (typically paper or cardboard) without the need for heat. This process contrasts with the traditional hot foil stamping method, which requires the application of heat and pressure to transfer the foil onto the substrate.

The cold foil process involves the following steps:

Application of Adhesive: A UV-curable adhesive is printed onto the desired areas of the substrate using conventional printing plates.

Foil Transfer: The metallic foil is pressed onto the adhesive-coated areas.

Curing: UV lamps cure the adhesive, securing the foil to the substrate.

Separation: The carrier film of the foil is removed, leaving behind the metallic foil adhered only to the adhesive-coated areas.

Benefits of Cold Foil Technology

- Cost-Effective: Cold foil machines eliminate the need for expensive dies and lengthy setup times associated with hot foil stamping, making them more cost-effective, especially for short runs and custom jobs.

- Eco-Friendly: Unlike hot foil stamping, which consumes significant energy due to the heating process, cold foil technology uses UV curing, which is generally more energy-efficient. Additionally, it produces less waste.

- Versatile: Cold foil can be applied to a wide range of substrates, including papers, boards, and even plastics, offering greater flexibility in design and material choices.

- High Speed: The cold foil process can be integrated into existing printing presses, allowing for high-speed production and inline application, which increases efficiency and reduces turnaround times.

- Exceptional Detail: Cold foil machines can achieve fine details and intricate patterns that are often challenging with hot foil stamping, providing superior precision and quality.

Applications of Cold Foil Machines

- Packaging: One of the most common applications of cold foil stamping is in the packaging industry. It is used to enhance the visual appeal of product packaging for cosmetics, food and beverages, pharmaceuticals, and luxury goods.

- Labels: Cold foil is widely used in label printing for wines, spirits, and other premium products. The reflective qualities of the foil add a touch of elegance and sophistication.

- Promotional Materials: Brochures, business cards, and promotional items often utilize cold foil to highlight logos, text, and decorative elements, making them stand out and catching the recipient's eye.

- Book Covers: Publishers use cold foil to create striking book covers that attract attention on bookstore shelves. The metallic sheen adds a layer of visual interest that can convey quality and value.

- Greeting Cards: The greeting card industry benefits from cold foil technology by adding shimmer and shine to designs, making cards more festive and appealing for various occasions.

Conclusion

Cold foil machines represent a significant advancement in the printing and packaging industries, offering a versatile, cost-effective, and environmentally friendly alternative to traditional hot foil stamping. Their ability to produce high-quality metallic finishes quickly and efficiently makes them an invaluable tool for businesses looking to enhance the visual appeal of their products. As the technology continues to evolve, cold foil applications will undoubtedly expand, driving innovation and creativity in design and production.