How does the automatic screen printing machine perform screen printing transfer?

Manufacturers of automatic screen printing machines tell you that screen printing refers to using a screen as a base and making a screen printing plate with graphics through a photosensitive plate-making method. Screen printing consists of five major elements, screen printing plate, squeegee, ink, printing table, and substrate. Screen printing is one of the most important forms of artistic creation at present.

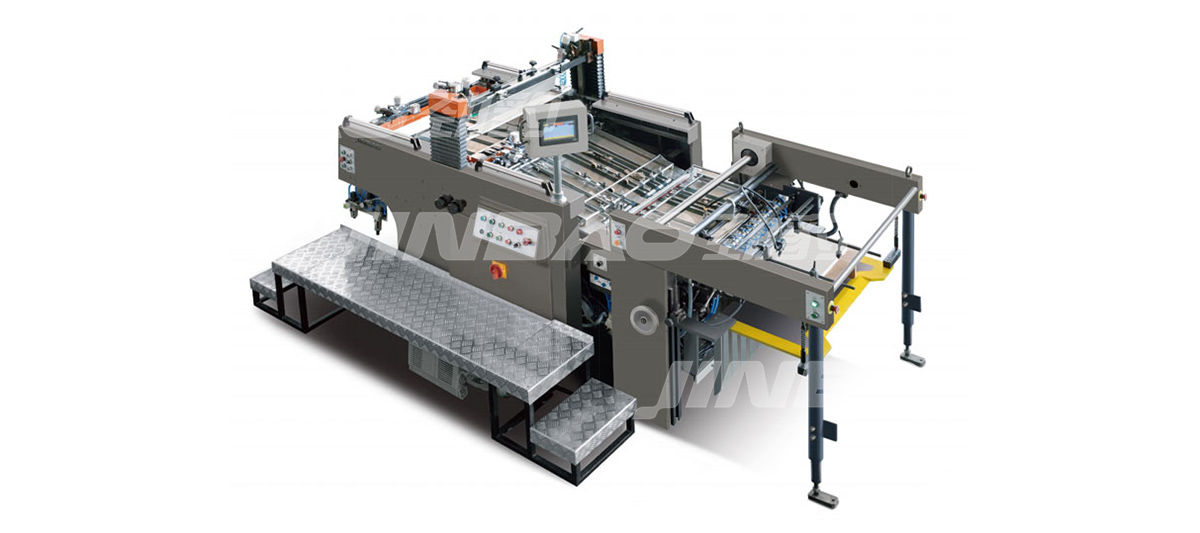

JB-106AS Automatic Servo Motor Control Screen Printing Machine For Spot UV (Servo Version)

What is an automatic screen printing machine?

The process of transferring a stenciled design onto a flat surface using a screen, ink, and squeegee. Fabric and paper are the most common screen printing surfaces, but with specialized inks, it is also possible to print on wood, metal, plastic, and even glass. The basic method involves creating a stencil on a fine mesh screen, then passing ink (or paint, in the case of artwork and posters) through to imprint the design on the underlying surface.

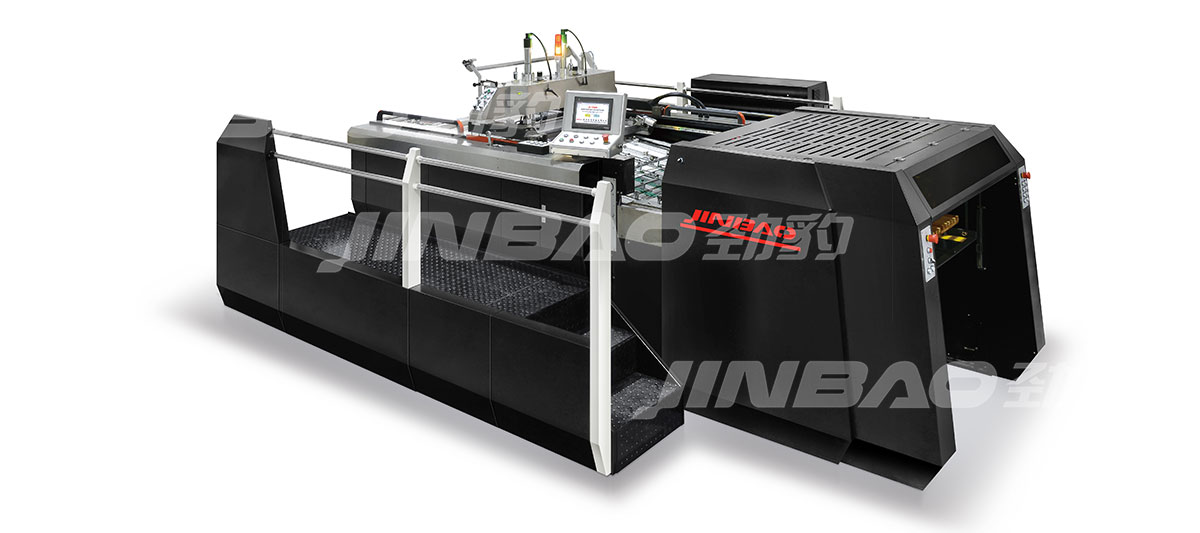

JB-78C Automatic Stop Rotary Screen Printing Machines (Servo Version)

How to use an automatic screen printing machine for thermoset ink transfer?

Screen printing heat transfer printing is printing the heat-set ink on a special "release" paper in advance, and then putting it into an oven to partially cure the heat-set ink. The graphic on the decal paper is then transferred (or printed) onto a T-shirt or garment using a heat transfer machine. If the transfer is printed on the T-shirt through a special "thermal separation", then the pattern will feel the same as direct screen printing on it.

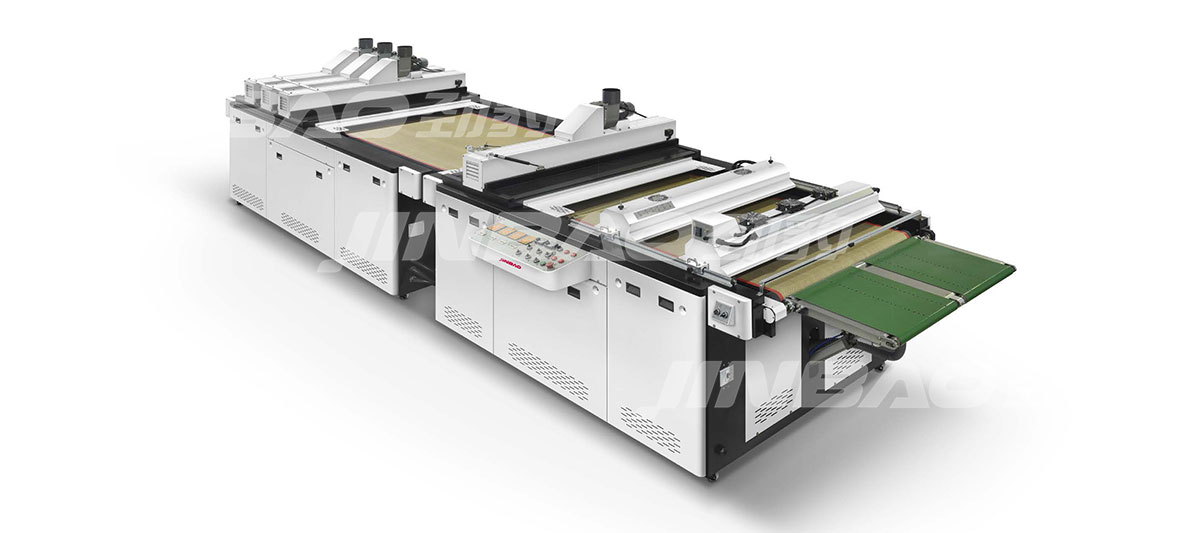

JB-720AQ Electrical And Electronic Production Line (Mechanical version)

Why use an automatic screen printing machine?

One of the reasons screen printing is so widely used is because it produces vibrant colors even on darker fabrics. The ink or paint also sits in multiple layers on the surface of the fabric or paper, giving the print a pleasing tactile feel. The technique is also favored because it allows printers to reproduce designs multiple times with ease. This is useful for creating multiple copies of the same garment or accessory since the same mold can be used to replicate a design over and over again.