What is the stacker used for?

For a long time, the paper feeding method in the printing operation is mainly manual handling, and the dust removal method is not ideal. Not only caused the staining of the paper surface, the decline of the yield, but also wasted a lot of labor. With the continuous improvement of printing quality requirements for modern printing products, higher requirements are also put forward for paper processing, which in turn urges the production of paper multi-directional finishing equipment. The paper pile sorting machine can automatically complete the paper pile tidying, loosening, dust removal, and turning process, which saves labor and avoids the influence of manual operation on the surface of printed matter. It is a necessary auxiliary equipment in the printing process.

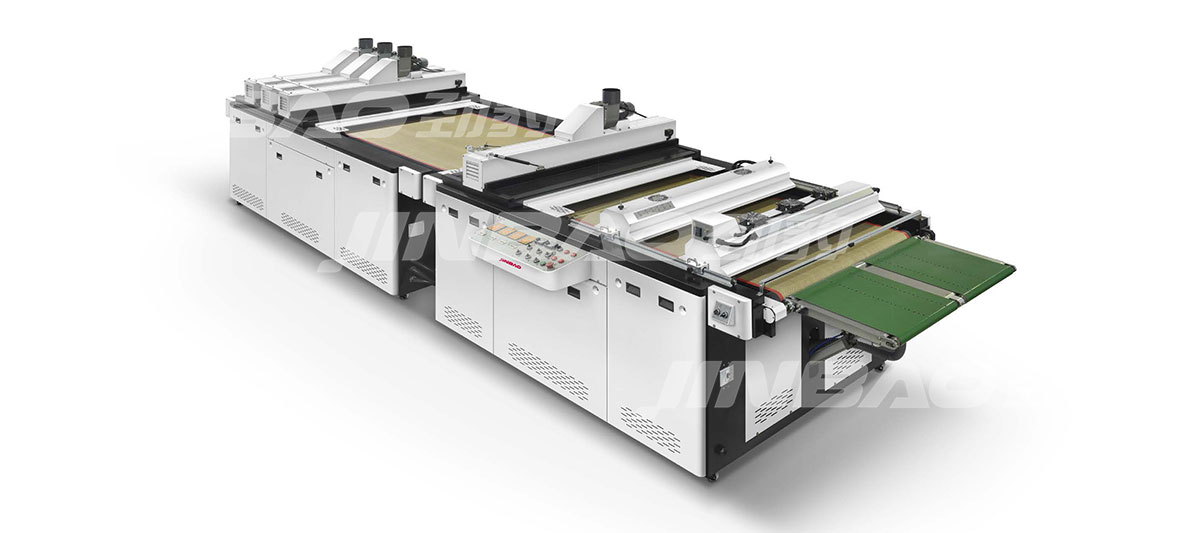

Stacker, also known as automatic stacker, paper pile turning machine or paper rewinding machine, its functions include paper turning, blowing, removing impurities, drying, alignment, paper punching and paper loosening, and its uses are as follows:

use before printing

1. It can remove impurities such as paper wool and paper scraps, improve the surface quality of the paper to be printed, and reduce the possibility of double-feeding; due to the improvement of the paper surface quality, the speed of the printing machine can be increased by 3%-5%. Labor productivity;

What is the purpose of the paper pile finishing machine?

2. It can replace pre-coded paper, saving time and effort; it can also be used for double-sided printing.

3. It greatly reduces the situation of impurities such as paper wool and paper scraps entering the printing machine, and prolongs the life of the printing machine;

4. Due to the substantial reduction of waste and defective products caused by impurities such as paper wool and paper scraps, the yield of finished products can be increased by 2%-3%.

Use after printing, in transfer stations, before paper cutting and die cutting

1. It can remove dusting, accelerate ink drying, and quickly reduce the odor of printed sheets due to ink solvents (this is very important for food packaging);

2. Prevent the occurrence of quality problems such as sticking sheets and back rubbing;

3. Save a lot of manpower.

It is understood that sheet-fed printing plants in European and American countries are generally equipped with several paper pile finishing machines.

According to the current domestic labor and printing costs, the payback period of a piece of paper pile finishing machine of our company is only 6 months for the user. However, the benefits reaped are long-term.

In terms of operation and use, the equipment occupies a small area, is easy to operate, and is easy to learn and use. At the same time, it has four functions of paper alignment, loose paper, dust removal and flipping. The blowing is controlled separately by two fans, and the wind force is adjustable, which can be selected according to needs. All the vibration trays adopt an integrated structure, and are connected with the turning body by a special elastic body to ensure sufficient vibration intensity. While vibrating, it also has the function of aligning paper. Equipped with a hydraulic system to control the turning of the paper pile and the pressure between the splints to ensure the smooth operation of the machine during work. This equipment can complete the sorting work of a whole rack of paper within five minutes, and is an indispensable auxiliary tool for printing plants.