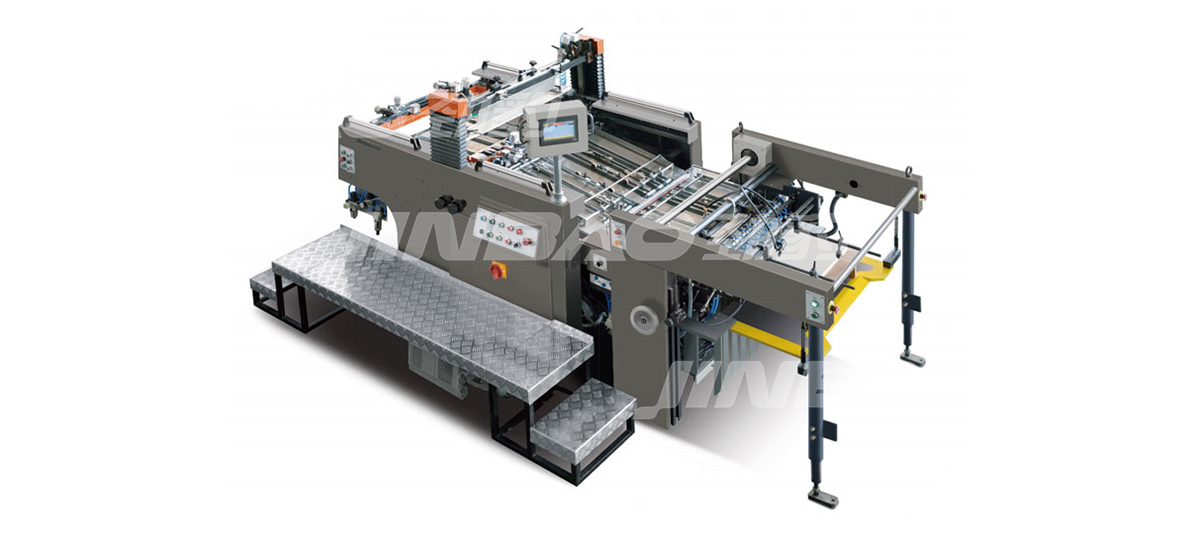

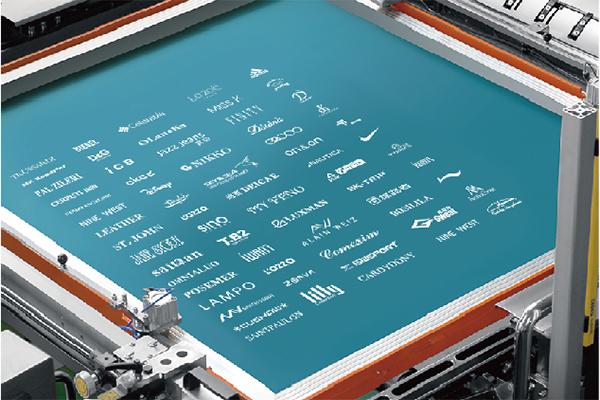

The production is mainly used in industrial printing, suitable for film printing with high precision of electric, electron, home wiring, auto etc such kinds productsglass, automobile and motorcycle, fishing pole and sports supplies; Meanwhile, it is also used for printing and drying of scratch ink of lottery ticket, various banking card and package printing matter of paper and plastic. Since selling in market, with its reliable performance, cost-effective, easy maintenance, good service and support, win the vast number of users`trust and praise.

| Model | JB-720AQ (Front pick-up feeder) |

| Max. Material size | 510x 720mm |

| Min. Material size | 270x350mm |

| Max. Printing size | 520x 720mm |

| Boarder | ≤10mm |

| Frame size | 880x880mm |

| Printing speed | 400~2200Pcs/h |

| Power | 3 Φ 380V 50Hz 8.89Kw |

| Compressor | 50L/h 4-6Kgs/cm2 |

| Weight | 3500Kg |

| Overall size | 3.05 x 2.24 x 1.68m |

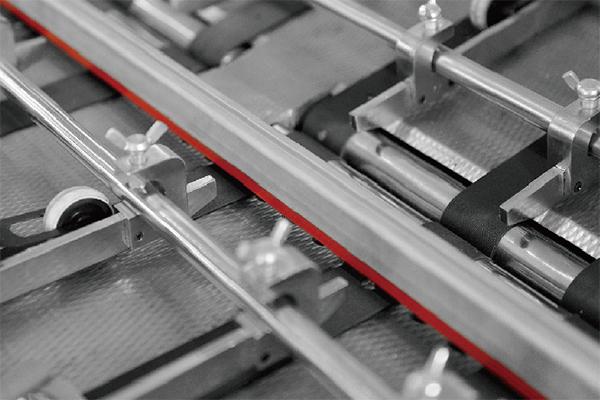

The suction system on the front edge of the feeder prevents the surface of sensitive substrates from being scratched when feeding, suitable for printing electrostatic or easily scratched substrates such as thin sheets and films even for multicolor printing, the surface of substrates will have no scratches.

Open stacking board can be lifted or lowered as a whole. Aligned papers just can be directly pushed in when feeding, convenient and time-saving.

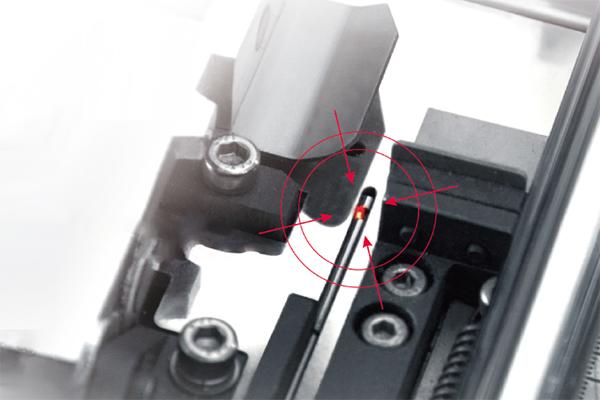

The optoelectronic double sheet detector does not touch substrates during detection, so as to avoid scratching them.

The feeder is equipped with anti-static device (plasma tuyere) to make it easier for the separation of substrates and for the delivery of sheet substrates. The feed board and delivery board can be added with anti-static bar.

Plasma tuyere is used to eliminate static electricity on the surface of substrates.

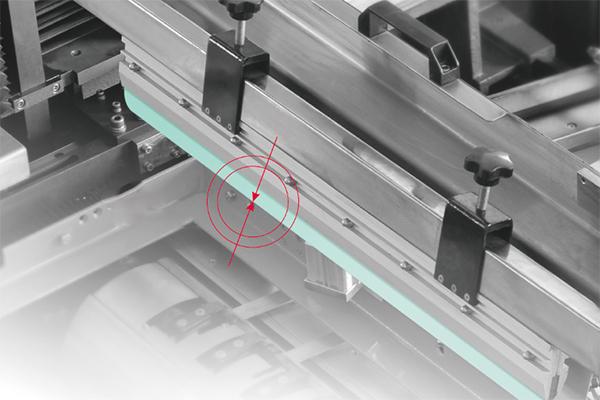

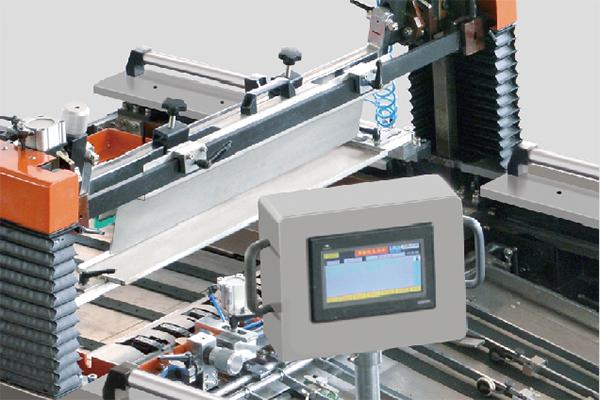

When substrates arrive at the location of the front and side lays, automatic registration is completed by the CNC sensor. If there is any tiny misplacement or substrate running, the screen printing machine will stop working automatically to ensure high accuracy of overprint and reduce reject ratio.

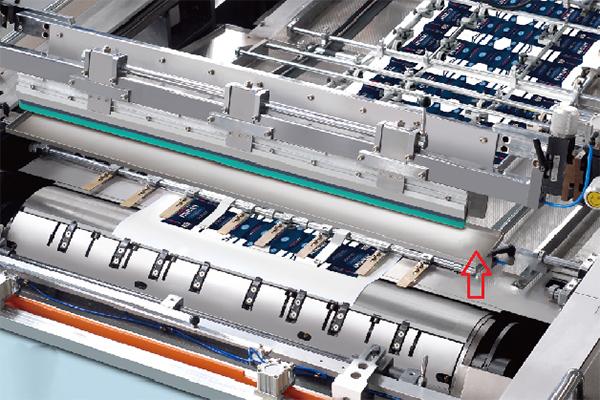

The surface of the delivery board is fitted with rice grain stainless steel plate that can reduce 30%~70% friction force between the substrate and the board surface to reduce surface abrasion. Meanwhile, controllable absorption device is used to fit for multiple materials.

The lifting and lowering of the squeegee system are controlled by cams and the pneumatic pressure kept device is fitted to ensure uniform printing pressure so that both spot and coat can be accurately printed out.

The substrate delivery system can ensure smooth delivery of printing part output and of subsequent drying part input. The delivery board can be folded down to facilitate to clean the screen, mount and dismount the squeegee and flood bar.

The weight of the printing cylinder is reduced by 28% while the strength and precision are higher. The vibration during operation is also lowered and the stability improved, which effectively prolongs the machine's service life.

PLC system is employed to centrally control the operation of the whole machine, supporting touch screen/button dual operating system and with automatic fault diagnosis and real-time display functions. It is easy to operate and improves the reliability and stability of equipment operation.

Suction nozzle device, each suction head is under independent control.

The screen frame can be pulled out, both facilitating substrate register or feeding adjustment and making it safer and faster to clean the cylinder and screen.

Ink dropping pan to prevent ink from dropping.

If you have any enquiry about quotation or cooperation, please feel free to email us jbprint@cn-jinbao.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

The graphic arts manufacturing sector is witnessing a paradigm shift with the emergence of advanced cylinder-driven screen printing systems. Two distinct technologie...

Release Time:2025-04-17Heat press and screen printing, or silkscreen, are two of the most widely used techniques for businesses and creators looking to customize clothing and merchandise. ...

Release Time:2025-04-14Textile printing is a vital process in the fabric manufacturing industry, allowing for intricate designs and vibrant colors on various materials. Two of the most com...

Release Time:2025-03-31

GET A QUOTE