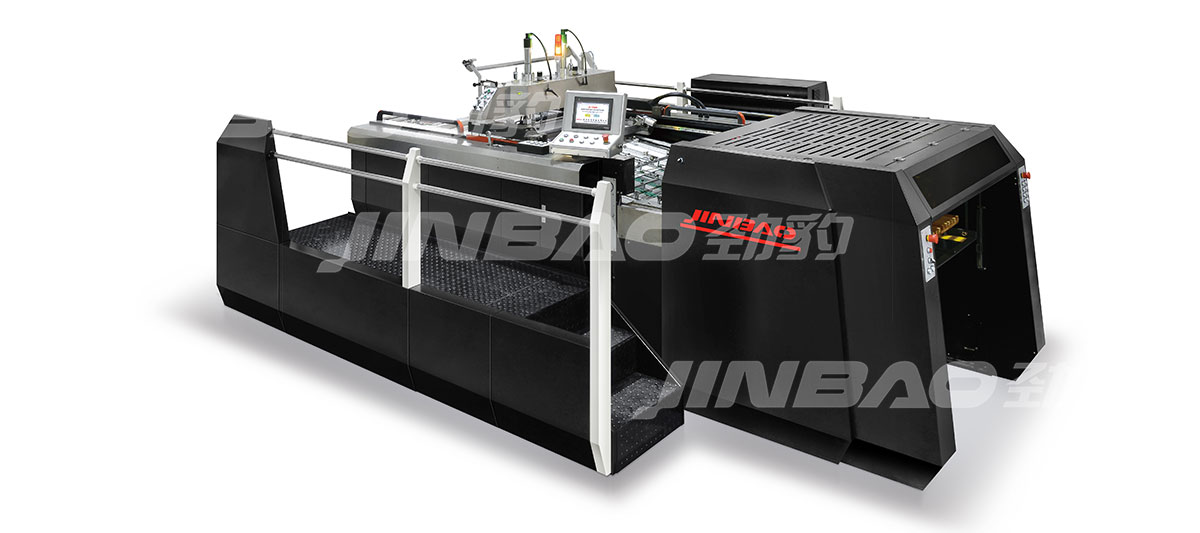

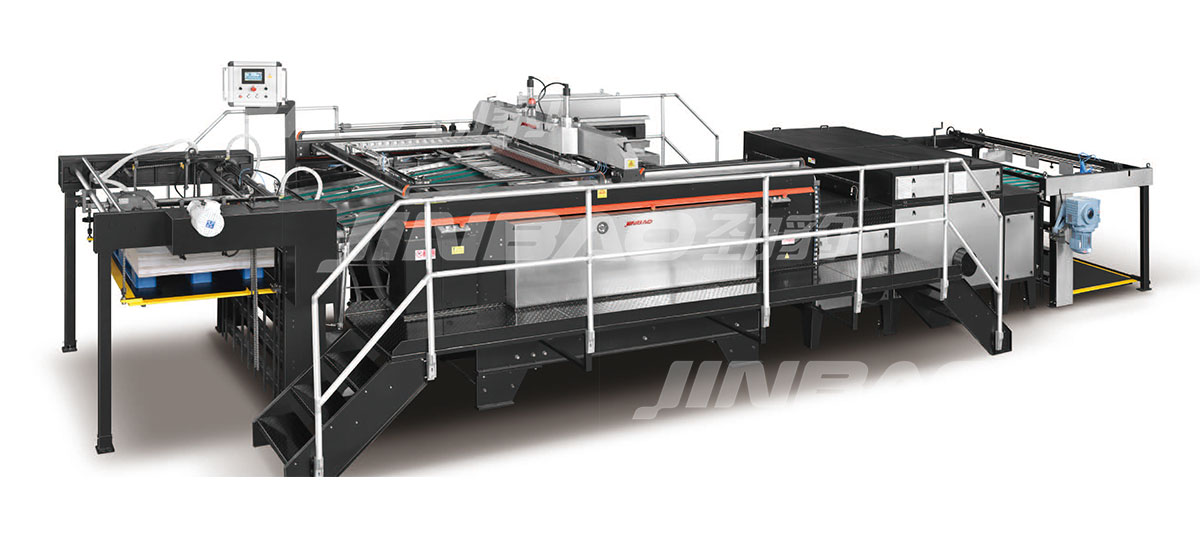

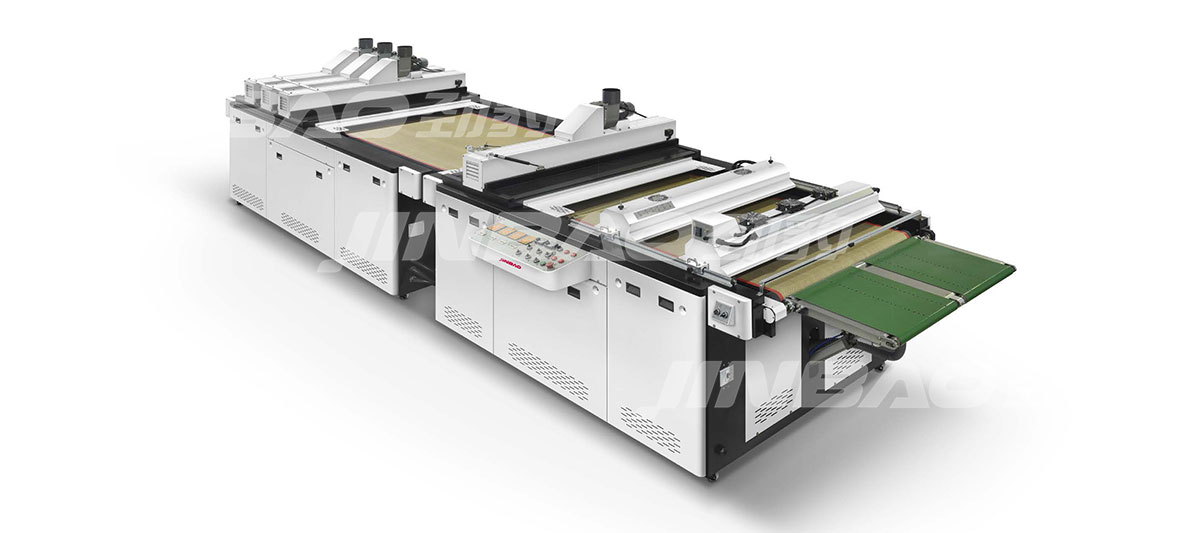

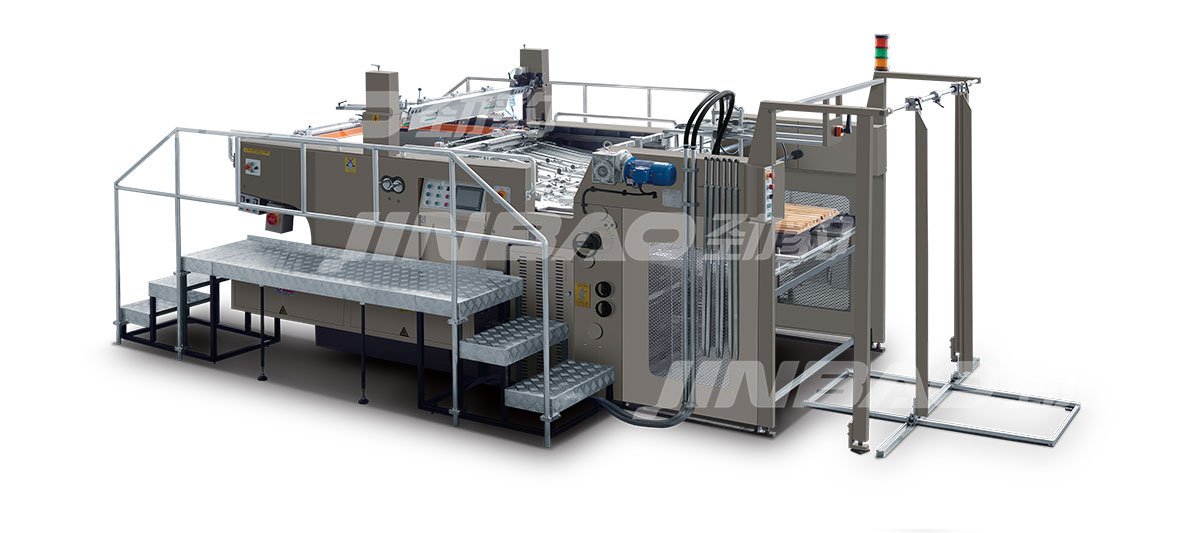

Screen printing characteristics and quality determinants of automatic screen printing machines

In this article, Zhejiang Jinbao Machinery Co., Ltd. will tell you about the screen printing characteristics of the fully automatic screen printing machine, the factors that determine the quality of screen printing, and what factors determine the amount of ink.

Features of Automatic Screen Printing Machine

①Wide adaptability: the screen printing format can be large or small;

②Thick ink color: Among all printing processes, screen printing has the thickest ink layer, high saturation, and better spot color printing effects;

③ Low cost: Screen printing is easy to make and the printing process is simple;

④ The quality of printed matter is stable;

⑤ Low production efficiency: Screen printing is slow and not suitable for online production;

⑥Low image accuracy: The screen printing resolution is not high, and the conventional screen line number is 24 lines/cm to 32 lines/cm.

Determinants of the Quality of Automatic Screen Printing Machine

1. The screen must have a certain strength and wear resistance to ensure good stretching and printing requirements and can meet the printing of large quantities of products and the recycling and reuse of screen plates.

2. The silk screen requires smooth and clean lines, uniform mesh size, square shape, symmetrical density, small elongation, and low shrinkage to avoid mesh deformation or mesh clogging and to facilitate the production of printing plates and the implementation of printing operations.

3. The wire mesh should be resistant to chemicals and have strong acid resistance, alkali resistance, and aging resistance. The influence of various solvents, inks, and slurries should be reduced to a minimum. The film should be easy to scrub. The printing plate image can be preserved and the printing plate will not become brittle and scrapped due to long-term storage.

4. The screen should have a certain degree of resilience. The resilience should not be too large or too small. If the screen is too large, the edges of the image will be unclear when printing; if it is too small, it will be difficult to print with the squeegee. Reasonable elasticity should be determined based on various factors such as image size, the distance between the screen frame and the substrate during printing, and station scheduling of ink and paste.

What factors determine the ink volume of Automatic Screen Printing Machines in screen printing?

1. Silkscreen:

A. For wire mesh with different mesh numbers, the lower the mesh number, the more ink will be deposited, and the higher the mesh number, the less ink will be deposited.

B. For silk screens with the same mesh number but different wire thicknesses, the thicker the wires, the greater the amount of ink that will be deposited. On the contrary, the thinner the wires, the less ink will be deposited.

C. For wire mesh with the same mesh number and the same wire thickness, more ink will be printed on the oblique screen, while less ink will be printed on the straight screen.

D. When other conditions are the same, the greater the tension of the screen, the greater the amount of ink.

2. Ink:

A. Ink dispensability.

B. If the ink is thin and the ink is discharged more if the ink is relatively dry, it will cause a drying phenomenon on the screen, and the ink discharge will be reduced accordingly.

3. Film thickness of photosensitive paste: The thicker the thickness of photosensitive paste during plate making, the more ink will be deposited. This method is commonly used in the process of increasing ink thickness.

4. Factors in the scraping process: If the scraping speed is slow, the ink film layer will be behind. If the scraping speed is fast, the ink layer will be thin.

5. Scratching knife: This is also crucial.

A. The more inclined the scraper is, the greater the amount of ink will be applied. If it is too vertical, the amount of ink will be reduced.

B. The softer the scraper, the larger the ink will be. On the contrary, the harder the scraper, the less ink will be deposited.

C. The rounder and blunter the blade of the scraper, the more ink will be deposited, and the sharper the blade, the less ink will be deposited.

The above are the screen printing characteristics of the Automatic Screen Printing Machine introduced by Zhejiang Jinbao Machinery Co., Ltd, the factors that determine the quality of screen printing, and what factors determine the amount of ink. A screen printing machine is a machine that uses a screen printing plate to print. It is a type of printing machine. A screen printing machine is a machine for printing text and images. It is a general term for machines or equipment used to produce printed matter.