Jinbao manufacturers let you know the purpose, type, working principle, use method and maintenance of the screen printing machine

What is a screen printing machine?

According to Jinbao screen printing machine manufacturers, with the development of the times and the progress of society, people have been unable to be interested in some monotonous things. No matter what we usually see, use, or drink there are some new requirements, and this requirement is about the aesthetics of the outer packaging. For example, when buying a notebook, you will see whether the cover looks good, whether the paper has any characteristics, and so on.

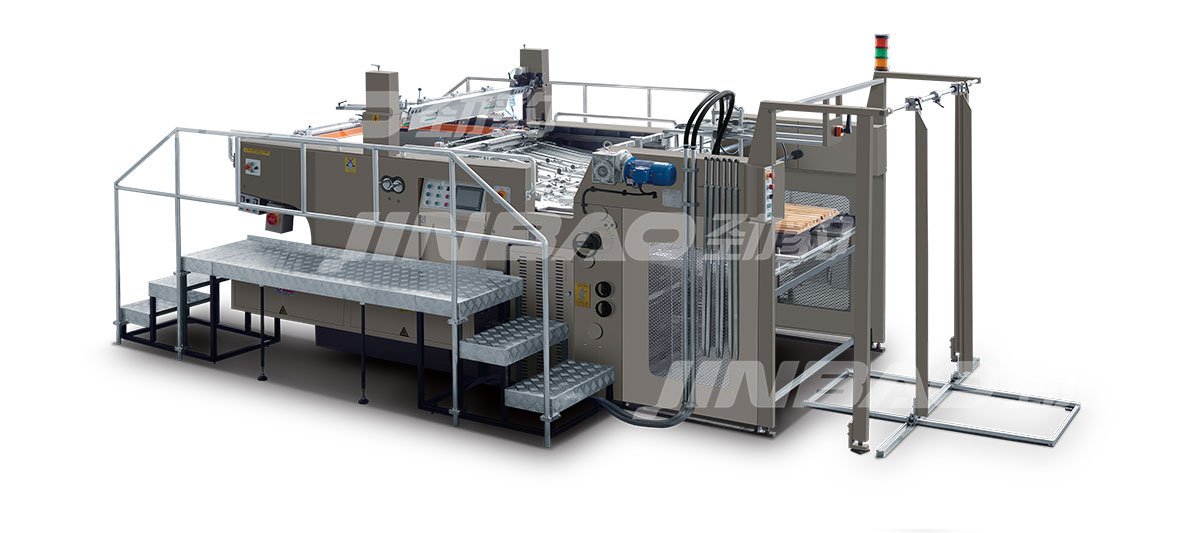

No matter what needs to be color-printed on the outer packaging, it must be printed with a screen printing machine, which can make the work more stable. When the customer needs what kind of screen printing machine, the printing effect is very good, so the customer's goods are no longer so monotonous. A screen printing machine is a machine that prints text and images and is a general term for machines or equipment used to produce printed matter.

Types of Screen Printing Machines

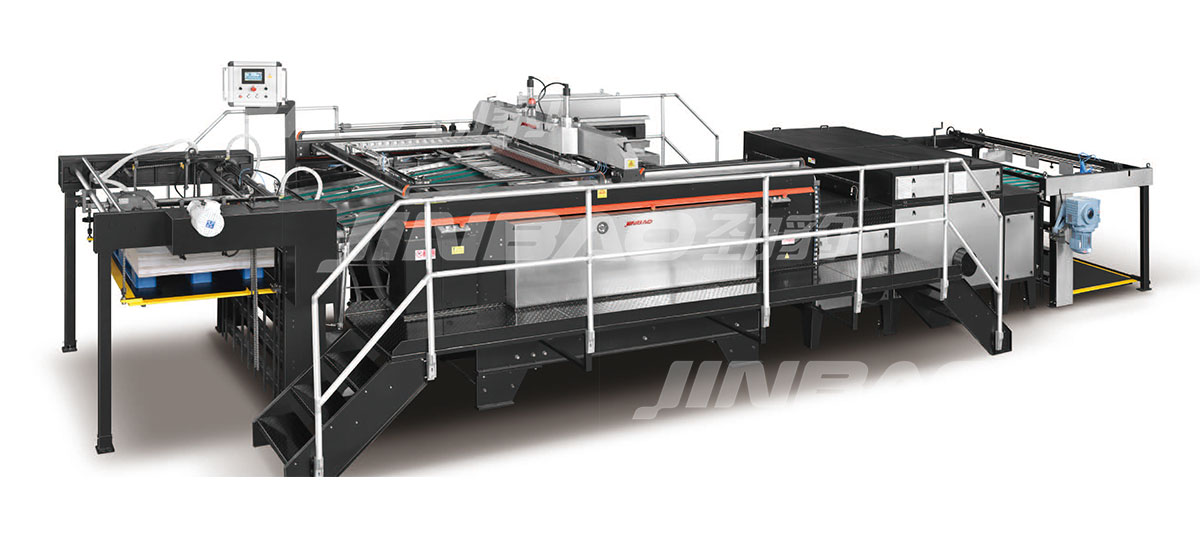

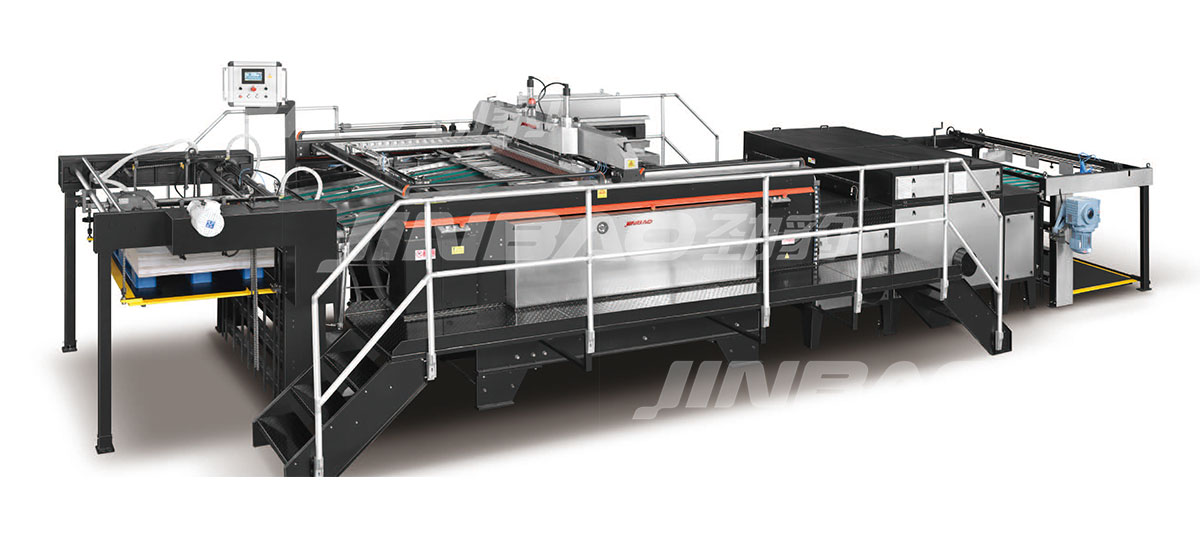

It can be divided into flat screen printing machines, curved screen printing machines, rotary screen printing machines, etc. Let Jinbao screen printing machine manufacturers introduce them separately.

Flat screen printing machine

A device that leaks solder paste or patch glue onto PCB pads through a silkscreen, uses a microcomputer control system, the digital circuit as the main control, and an automatic brake clutch system, making the whole machine more stable and printing more precise, The operation is safer, the guide rail adopts square rail, and the squeegee uses pneumatic up and down to keep the same pressure during printing, and can be adjusted from 0 to 450.

Curved screen printing machine

The curved screen printing machine belongs to stencil printing. The most basic principle is to scrape the ink through a squeegee, so that the ink oozes out from the place where there are small holes in the pattern of the screen printing screen, and deforms by the pressure of the squeegee, so as to contact with the surface of the substrate. , And the surface of the substrate can also be decomposed into countless small planes, so as to realize printing.

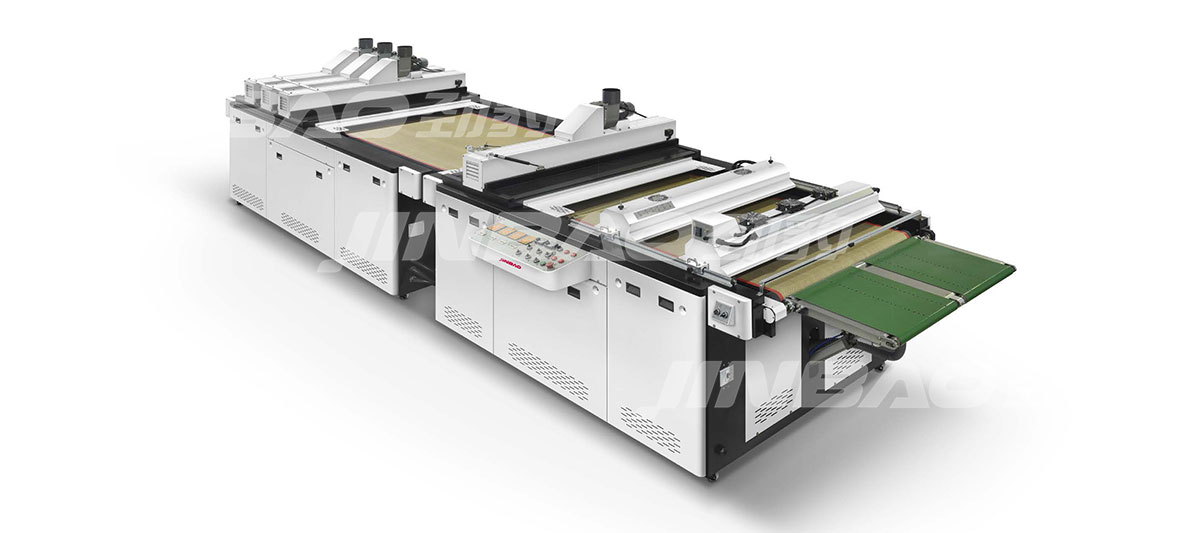

Rotary screen printing machine

Using a cylindrical screen plate, a wedge-shaped squeegee or a squeegee stick is installed inside the cylinder, and the linear speed of the rotation of the printing plate and the movement of the substrate is the same.

How screen printing machines work

The power is transmitted through the transmission mechanism so that the squeegee squeezes the ink and the screen printing plate in motion so that the screen printing plate and the substrate form a pressing line. The force F2 and the rebound force make the screen printing plate not contact with the substrate except the embossing line. Under the action of the squeezing force F1 of the squeegee, the ink passes through the mesh and leaks from the moving embossing line to the printing plate. on the substrate.

How to use the screen printing machine

(1) Automatic screen printing machine: add automatic printing lifting, conveying, drying, and collecting and stacking mechanisms before and after the 3/4 automatic screen printing machine. The printing speed is significantly higher than that of the semi-automatic machine, with up to 1500 prints. /hour or more.

(2) Manual screen printing machine: It is generally composed of chain support, a printing platform, and a screen plate, and all actions are manually operated.

(3) Semi-automatic screen printing machine: The various actions during printing are partially automatic, and the rest are still manual screen printing machines. Generally, it is called a 14 automatic screen printing machine that squeegees ink, even ink, and screen frame automatically, and is said to be a 1/2 automatic screen printing machine that scrapes ink, even ink, screen frame, and substrate adsorption are automatic. In addition, the substrate feeding can also be automatically a 3/4 automatic screen printing machine.

(4) Screen printing linkage machine: It is composed of several groups of printing, drying devices and bronzing, creasing, film coating, die-cutting, and other devices in series. The substrate is continuously fed in a roll type, with automatic unwinding, automatic winding, and positioning control mechanisms, which can ensure stable speed, accurate overprinting, and consistent tension. The whole machine can be controlled by a computer. It is a high-efficiency and full-featured screen printing machine for printing multi-color prints.

Screen printing machine maintenance

(1) Before operating the screen printing machine, the operator must first check whether there is dust left by cutting chips at the joint between the moving rail surface and the rail surface of the screen printing machine, and at the same time, keep no oil stains, no wire drawing, no scratches, etc.

(2) If the screen printing machine is not used for a long time, the screen printing machine should be wiped clean and placed in a cool, dry, and ventilated environment.

(3) Novices cannot disassemble the touch screen at will without the guidance of a professional master, because it is easy to damage the touch screen.

(4) In the daily maintenance of the screen printing machine, it is strictly forbidden for the operator to disassemble the parts. When the screen printing machine fails, he must press the emergency stop switch immediately, then turn off the main power supply, and notify the maintenance personnel.

(5) The operator must regularly conduct state inspection, general survey, precise inspection, adjustment, failure analysis, and state monitoring of the screen printing machine equipment. There is also mechanical equipment, which cannot place workers, quantities, fixtures, tools and workpieces, raw materials, etc.

(6) Maintenance of screen printing machine parts. When adjusting the machine, be careful not to hit tight parts such as linear guides with hard objects, otherwise, the machine will be easily deformed, and you should also pay attention to cleaning the sliding parts in time to avoid foreign objects such as ink falling, which will affect their combination separation and adjustment work.

Summarize:

This article is about the use, type, working principle, usage, and maintenance of the screen printing machine. If you want to know more about the screen printing machine, you can pay attention to the knowledge module of Jinbao News, and we have many years of experience for you Provide relevant knowledge for free.