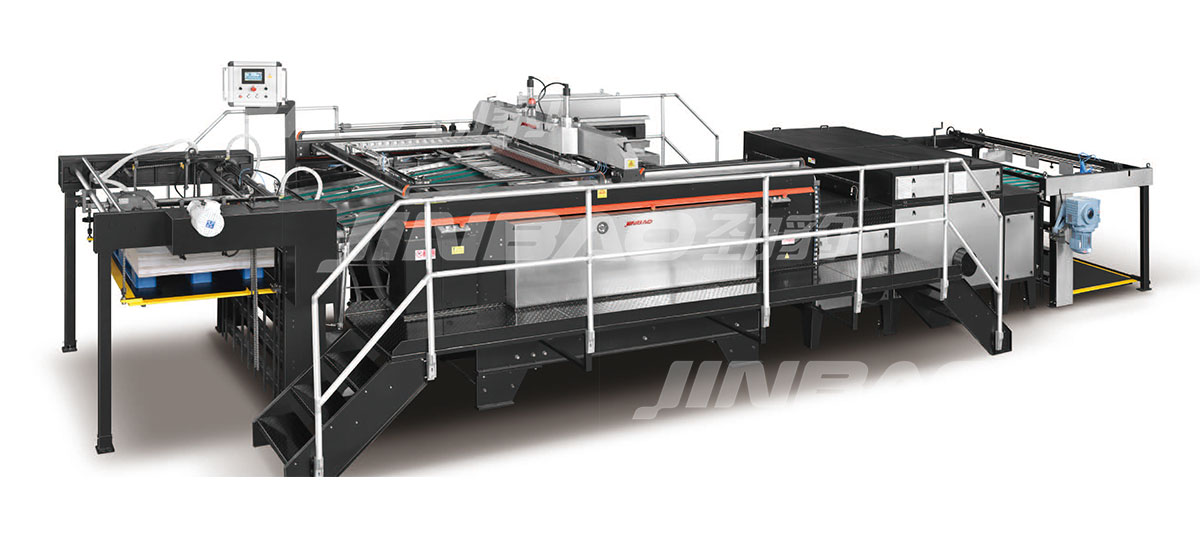

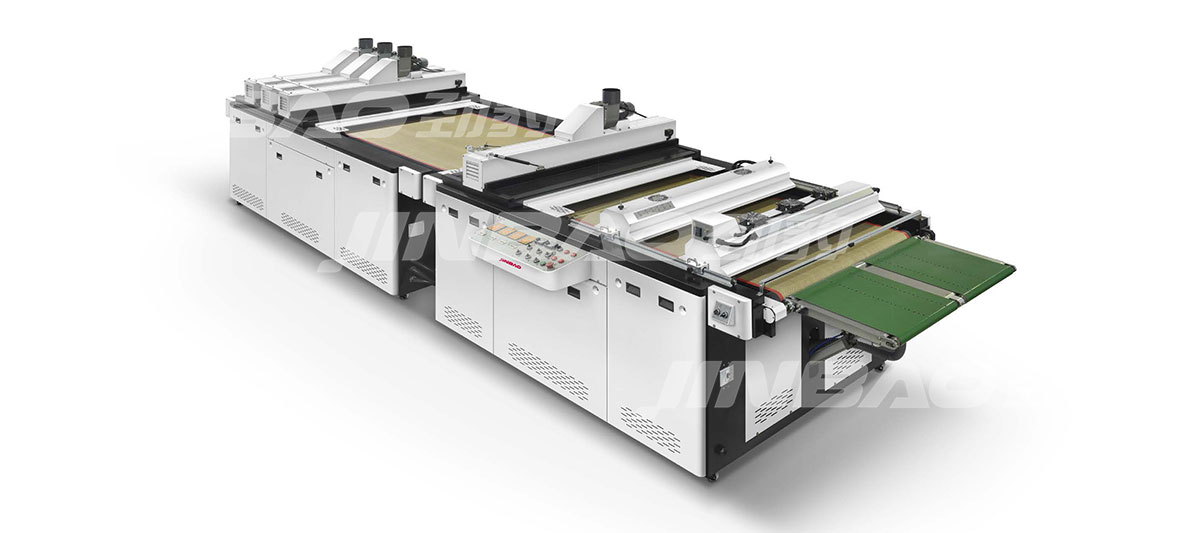

How to use a silk screen printing machine

How to use a silk screen printing machine?

Prepare your artwork:

Create or obtain the design you want to print onto the fabric or surface. Screen printing machine Tips, Make sure it is finalized and ready for transfer.

Choose the appropriate screen:

Select a silk screen that matches the size and resolution needed for your design. Ensure it is clean and free from any previous ink residue.

Set up the screen frame:

Attach the screen to the frame tightly, ensuring there are no gaps or loose areas.

Prepare the ink:

Depending on the type of ink you are using, mix it according to the silk screen printing machine manufacturer's instructions. Ensure you have enough ink for your desired number of prints.

Prepare the printing surface:

Place the material or substrate you want to print on either on a flat surface or secure it with a clamping system.

Position the screen:

Carefully position the screen over the material, making sure the design is correctly aligned and centered.

Apply the ink:

Pour a small amount of ink onto one end of the screen. Use a squeegee to evenly spread the ink across the screen while applying moderate pressure. Ensure that the entire stencil area is covered with ink.

Print the design:

Keeping the squeegee at a 45-degree angle, gently and evenly pull it across the screen, applying enough pressure to push the ink through the mesh onto the material beneath. Do this in one smooth motion.

Repeat the process:

Lift the screen carefully and check the print. If necessary, reapply the ink to the screen and repeat the printing process until you achieve your intended results.

Clean the screen:

Immediately after printing, remove excess ink from both sides of the screen using a squeegee or scraper. Wash the screen thoroughly with water and a gentle detergent to prevent ink from drying and clogging the mesh.

Remember, using a silk screen printing machine requires practice and experimentation to achieve desired results. Always refer to the specific instructions provided by the silk screen printing machine manufacturer for your equipment and materials.

Screen printing machine operation tutorial:

1. Before working, you must turn the power switch from green 0 to white 1, and confirm that the main power supply has turned on all the ventilation equipment and keep it running normally;

2. Wait for the computer to start automatically. After starting, the printing control program will be loaded automatically. The operator must wear protective masks and rubber gloves correctly before operating;

3. Take out the screen plate of the corresponding model, fix it on the screen plate fixing frame, install it on the machine, and press the F4 key to lock the screen plate. At the same time, you can hear the sound of "pop", and you can feel that the screen plate will not be able to be pulled out with your hands. Install the scraper and ink return knife, and transfer the corresponding process file.

4. Ink, acetone, and other chemical raw materials or auxiliary materials can only be collected for on-duty use, and stored in a dedicated storage cabinet, kept sealed, and must not be placed on the ground or the workbench;

5. All kinds of cleaning cloths, paper, environmental protection bowls, disposable plastic cups, stirring rods and other chemical wastes stuck with chemicals should be put into special trash cans, and the lids should be covered to keep them sealed. Littering is prohibited;

6. When repairing, cleaning, and maintaining the equipment, replacing and adjusting parts and accessories, you must cut off the power supply, turn off the power supply and air source before leaving get off work, and clean up the site before leaving get off work.