Five factors that determine the price of semi-automatic screen printing machines

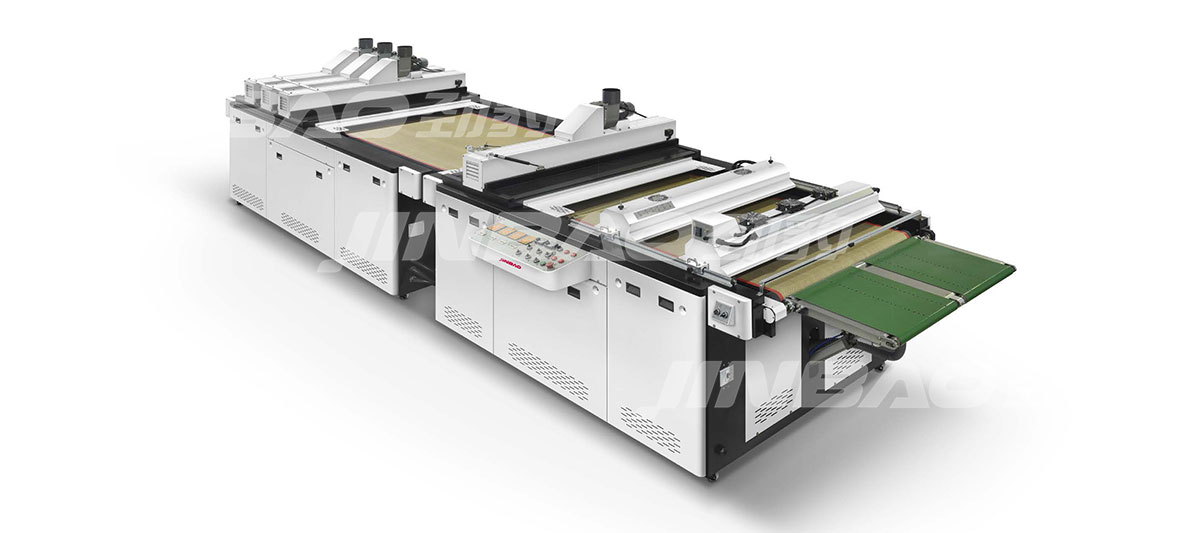

Just like buying a mobile phone, many friends will find that the price of screen printing machines is also uneven, and the price of the same type of screen printing machine will also vary greatly. The difference is even very large, so why do screen printing machines that look similar, and the price will vary so much? Semi-automatic screen printing machine manufacturers tell you.

Here I want to remind friends who need to know the price of semi-automatic screen printing machines. The main printing factors that affect the price of screen printing machines are as follows: materials; accessories; assembly capabilities; operation methods; packaging and transportation methods;

1. Selection of materials

In fact, the reason is very simple. The thickness of the steel that looks the same in appearance can’t be seen; this is a big difference. The price of thick steel is not one or two times worse than that of thin steel. It’s as simple as thickness In order to save material, the thin steel uses inferior raw materials, which are light and easy to bend and rust; the screen printing machines we produce all use national standard steel, and never use non-standard inferior materials. The advantage of this is that the screen printing machine produced is stable in structure, High durability, and reliable printing quality;

2. Differences in accessories

Everyone knows that the price of counterfeit products is very cheap, and the same is true for the selection of screen printing machine accessories. The price of accessories of the same specification, bought from Taiwan or abroad is much more expensive than buying from Shenzhen in Zhejiang, then the problem is Here we come, the same solenoid valve, there are more than a dozen models, and there are more than a hundred, the price difference is ten times, and the layman can't see the difference at all; the parts of the screen printing machine we use are all original big-name parts, In this way, the screen printing machine is reliable and safe;

3. Assembly ability

The screen printing machines installed by different masters are different. The equipment assembled by experienced masters is smooth, with better coordination, and the equipment is relatively easy to use; the equipment assembled by poor masters has poor stability and may be difficult to use. It takes a longer time to run in; at the same time, the wages of experienced masters are several times higher than that of ordinary masters. We hire experienced masters with high salaries to ensure the reliability of equipment assembly and to ensure that perfect equipment will be sent to your hands;

4. Operation method

The operation methods of screen printing machines can generally be divided into three types: manual, semi-automatic, and fully automatic. Screen printing machines have different operation modes, and they are also different in price. Among these three modes of operation, manual screen printing machines are cheap, such as manual suction screen printing tables; while semi-automatic screen printing machines and fully automatic screen printing machines The screen printing machine is relatively expensive because of its labor-saving operation method and high efficiency.

5. Packaging and transportation capacity

Stable packaging, and punctual and efficient transportation are our guidelines; Yisheng Machinery especially employs professional wooden box packing masters, the packaging is stable and reliable, and there are almost no accidents during transportation; at the same time, we cooperate with major brand transportation companies to ensure timely, efficient and reliable transportation ;

So, friends, please don’t say that the price of a semi-automatic screen printing machine is expensive. We must clearly understand what kind of structure, what kind of accessories, and what kind of workmanship the equipment adopts so that we can choose the right equipment;