Common faults and solutions of silkscreen machine, how to solve the blurred printing of the screen printing machine during the printing process

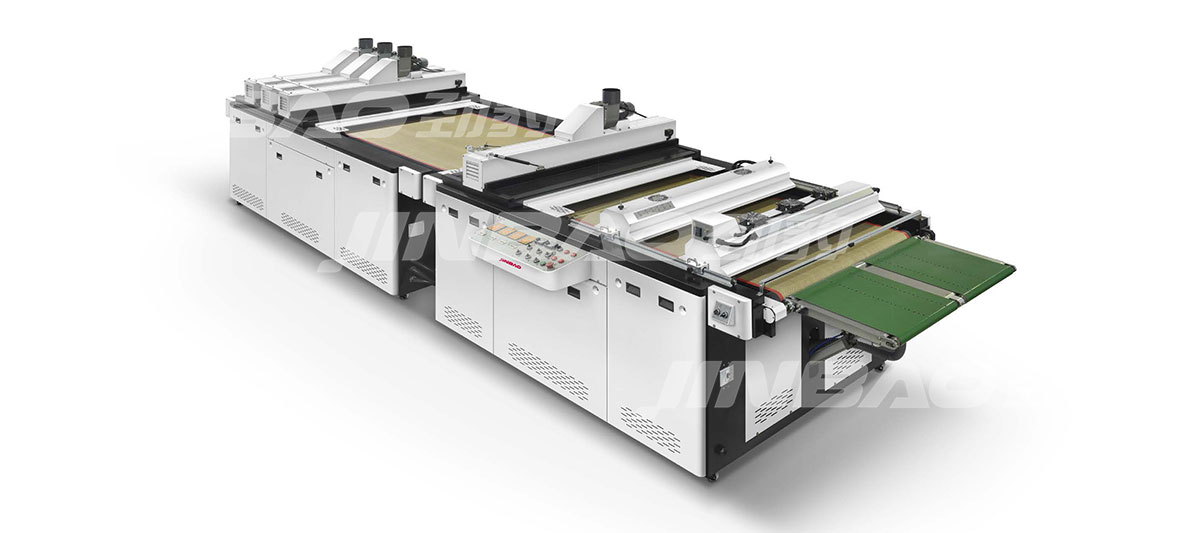

Screen printing has great flexibility and wide applicability. Today, Zhejiang Jinbao Machinery Co., Ltd will tell you about the common faults and solutions of screen printing. How to solve the blurred printing of the silkscreen machine during the printing process, let’s talk nonsense and talk about dry goods!

Reasons why the printing pattern of the silkscreen machine is not clear:

1. Improper selection of ink or quality problems of the ink itself, the ink dries too fast to make the printed patterns or lines unclear.

2. The viscosity of the ink is too high, resulting in incomplete patterns or broken lines.

3. The phenomenon of blockage occurs, which affects the normal over-inking of ink.

4. The pressure of the scraper is insufficient or uneven, resulting in uneven ink passing.

5. The surface of the substrate is uneven.

Solution:

1. Treat the surface of the substrate.

2. Pay attention to the uniformity of the scraping force and the strength of the scraper.

3. Dilute ink or add the thixotropic agent to reduce viscosity.

4. Replace the suitable ink and use a slow-drying solvent to prepare the ink.

Causes of ink plugging and webbing:

1. Add inappropriate solvents when adjusting the ink.

2. If the mesh is too high, the ink cannot pass through the mesh normally.

3. If the viscosity is too high, it will cause blockage when printing small characters or lines.

4. The ink itself dries quickly or the ink is diluted with a fast-drying solvent in a printing environment with high temperature.

Solution:

1. Select the appropriate mesh number.

2. Dilute ink or add the thixotropic agent to reduce viscosity.

3. The silkscreen machine manufacturer tells you that you can replace the slow-drying ink or use a slow-drying solvent to prepare the ink according to the environment.

Causes of Poor Ink Drying

1. Improper selection of solvents will corrode the substrate.

2. The solvent dries slowly or the drying time is insufficient.

Solution:

1. Choose an appropriate solvent.

2. Choose a quick-drying solvent or extend the drying time.

Reasons for poor ink adhesion:

1. The ink is not compatible with the substrate.

2. The surface of the substrate is not clean, with oil stains or surface treatment agents, etc.

3. Insufficient drying time, the ink is not fully cured.

4. Too many additives or the improper addition of additives.

Solution:

1. Correctly choose the appropriate ink.

2. Treat the surface of the substrate or replace the substrate.

3. Prolong the drying time so that the ink can be completely cured.

4. Correctly add related additives, too much defoamer will also affect the adhesion.

Reasons for water ripples in printed matter:

The ink is too thin or the viscosity is too low, and the screen distance is too low, resulting in ink sticking.

Solution:

Reduce the amount of solvent added to the ink, and properly increase the screen distance, so that the printing can rebound naturally.

How to solve the unclear printing of the silkscreen machine during the printing process?

Generally, the silk screen printing plate made by screen printing equipment must be dried with a hairdryer and then placed in the sun for several hours; it is better;

Before using the screen printing plate, first, check whether the patterns and fonts in the screen printing plate are clear. If there are some small spots around the pattern, it can be filled with patch glue; during the debugging process, the screen printing plate of the screen printing equipment should be kept parallel to the product bearing frame as much as possible, and the pressure of the scraper should be a little heavier to ensure that the screen printing plate will not be easily scratched;

Generally, in production, it is better to wipe the screen printing plate with 719 thinner, but do not use alcohol to wash the screen printing plate, because there is a part of the water in the alcohol, and contact with the screen printing plate will cause certain adverse conditions (such as the rubber sheet falling off., some relatively small fonts are easy to fall off);

A good screen printing plate can be used several times normally. If the output is relatively small during production, the screen printing plate should be removed and cleaned as soon as possible after completion. At the same time, do not use a knife during cleaning, you can use some hard After cleaning the silk screen printing plate, make sure that the patterns and fonts in the silk screen printing plate are clear, then dry it with a hair dryer, and then place it on the designated position.

The article is provided by: screen printing equipment https://www.cn-jinbao.com Zhejiang Jinbao Machinery Co., Ltd. If you encounter a problem and cannot solve it, you can contact us. We are a professional silk screen machine established in 19974 manufacturers.